Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

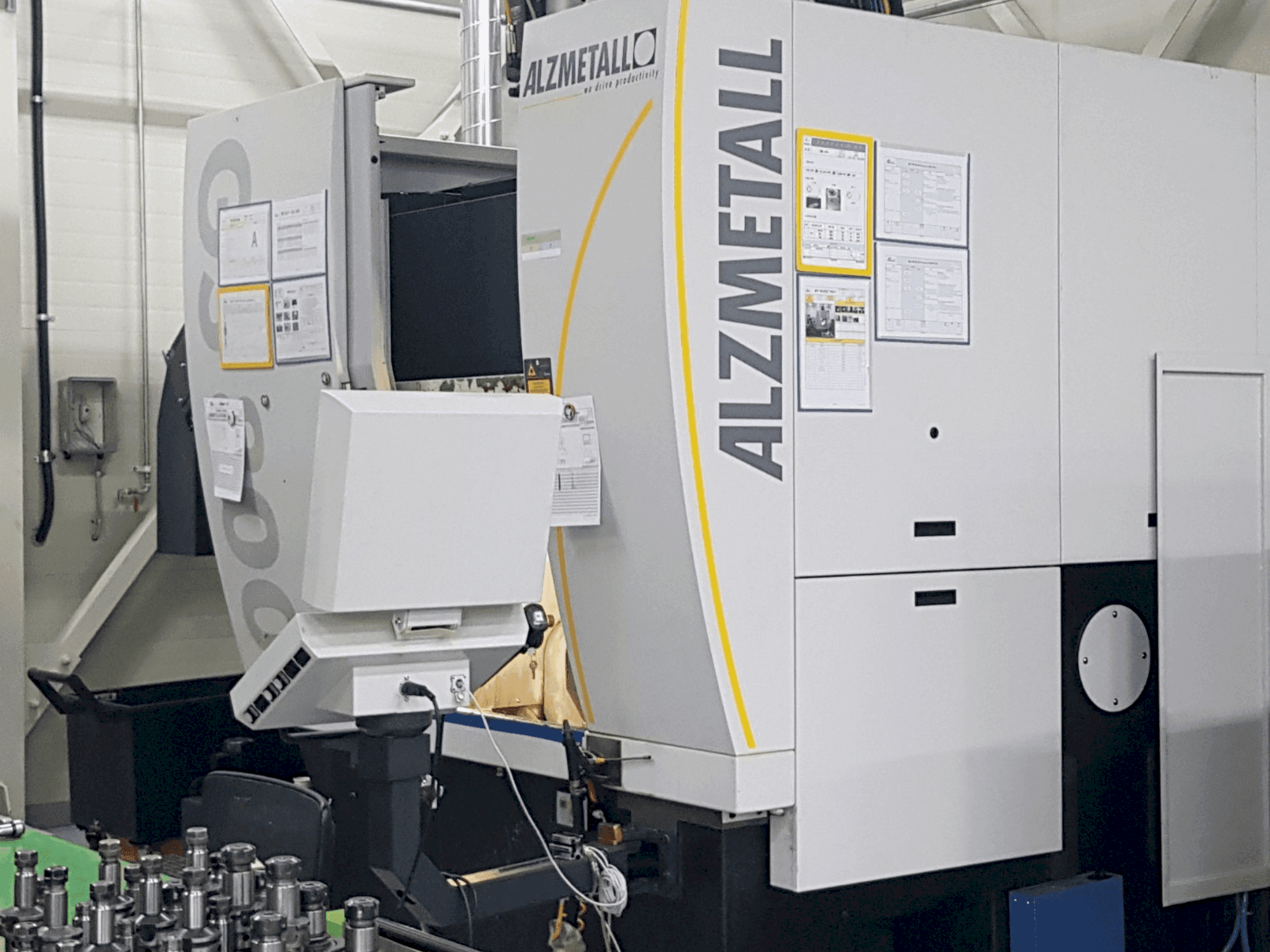

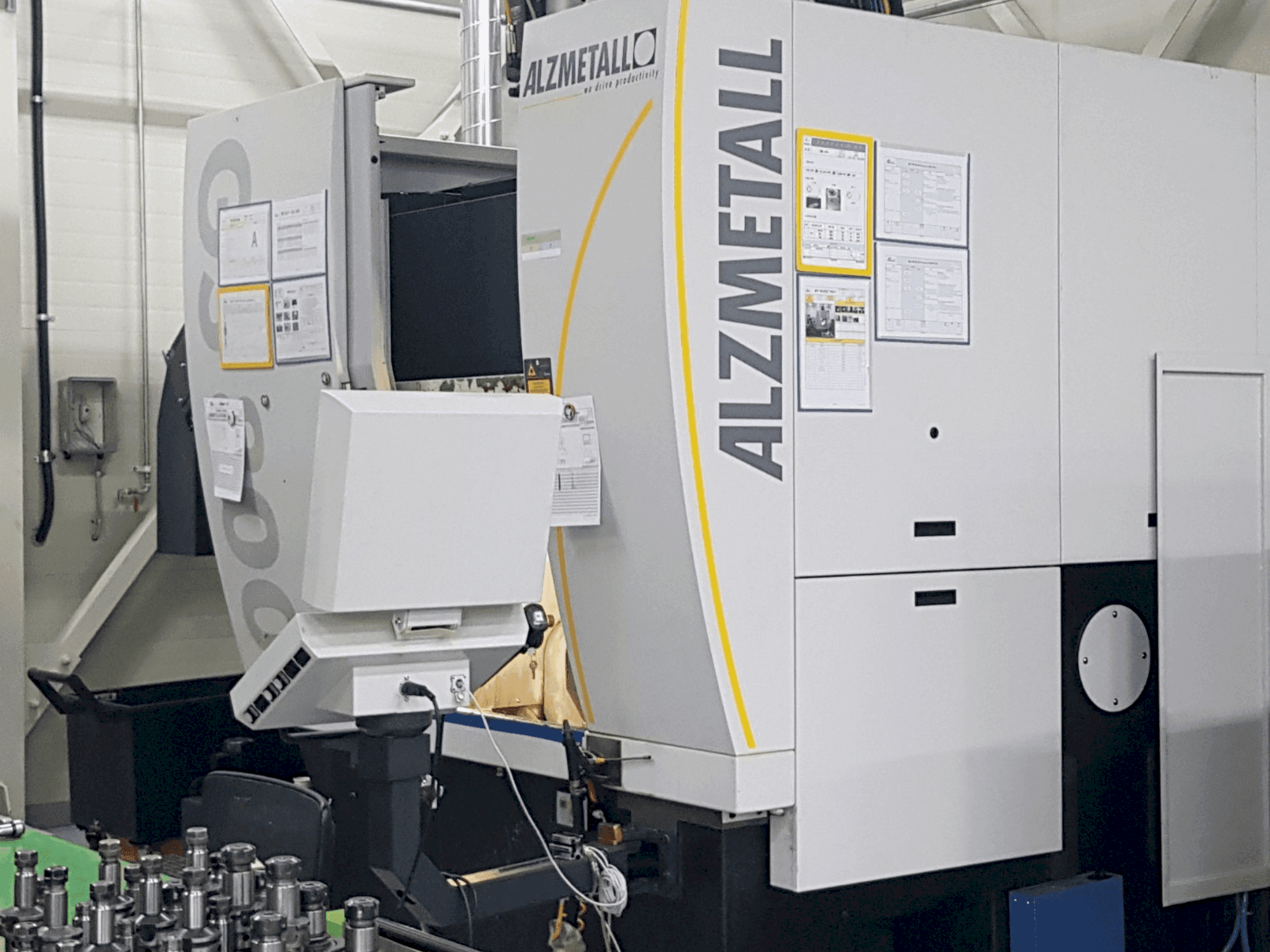

Alzmetall - GS800/5-TKR-MIL-ALZ-2015-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- Used Universal machining centre ALZMETALL GS800/5-T - 2015 - for sale | gindumac.com

This 5-axis ALZMETALL GS800/5-T universal machining centre was manufactured in 2015. It boasts advanced technology including Heidenhain TNC 640 control, 30,000 rpm capability with HSK A63, and high precision packages ensuring remarkable exactness up to TP 0.005mm for X, Y, Z axes. Enhanced features like dynamic collision monitoring, tool measuring via laser and a robust security compound window combine to offer peak performance and safety. The ALZMETALL GS800/5-T machine we have for sale is equipped to increase productivity and precision in complex machining tasks. For more information about this ALZMETALL GS800/5-T universal machining centre, please reach out to us.

Overview

- brand: Alzmetall

- year: 2015

- MODEL: GS800/5-T

- application type: Milling

- Location: South Korea

- machine type: Universal Machining Centre

- control unit brand: HEIDENHAIN

Technical Information - Alzmetall GS800/5-T

Control Unit

- Control Brand: HEIDENHAIN

- Control Model: TNC 640

Movement

- Number of Axes: 5

Technical Specification

- Spindle Speed: 30000 RPM

Additional Information

Additional equipment

- A & C axis torque motors

- Optical gauging with Kinematics opt (incl. calibration ball dia 30mm)

- Hand-wheel HR 410

- Dynamic collision monitoring

- Work probe TC 50 (BLUM)// Tool measuring via laser (BLUM)

- Dynex version (rapid travel max. 100m/mm)

- High precision package HPP (TP 0.005mm for X, Y & Z axis, TP 4” for C axis, TP 6” for A axis)

- Chip rinsing of working area// Emulsion mist extraction (LTA)

- Production package A (Chip conveyor, coolant cleaning by micro filter, through the main spindle 20bar, coolant band filter, air sealing for linear measuring system)

- Best surface kit (for true contours, better surface quality & Higher accuracy)

Machine Benefits

Qualitative Machine Benefits

- Mql system

- Security compound window (instead of polycarbonate window)

- Roll shutter roof protection (automatic opening & closing with coordinate drive system)

- Iox metal sheet cover (inside)

Technical Machine Benefits

- Various axis configurations for multi-directional machining

- High spindle speed for efficient cutting

- Precision control with heidenhain tnc 640

- Collision monitoring for safety

- Tool measuring via laser for accuracy

- Chip rinsing and mist extraction for cleanliness

- Frequency control and mql system for efficiency

Extra Information

Machine is under power.

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing