Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

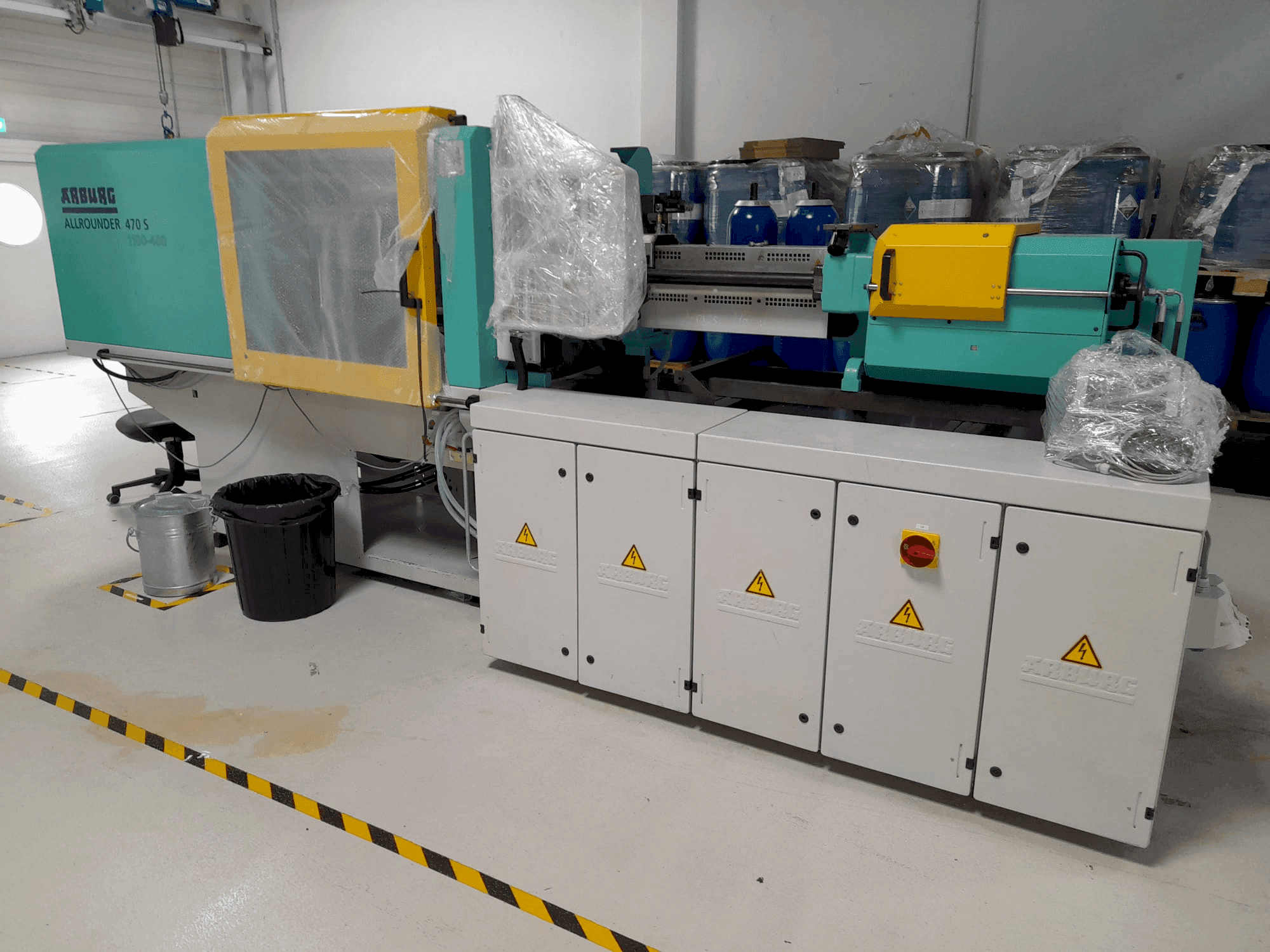

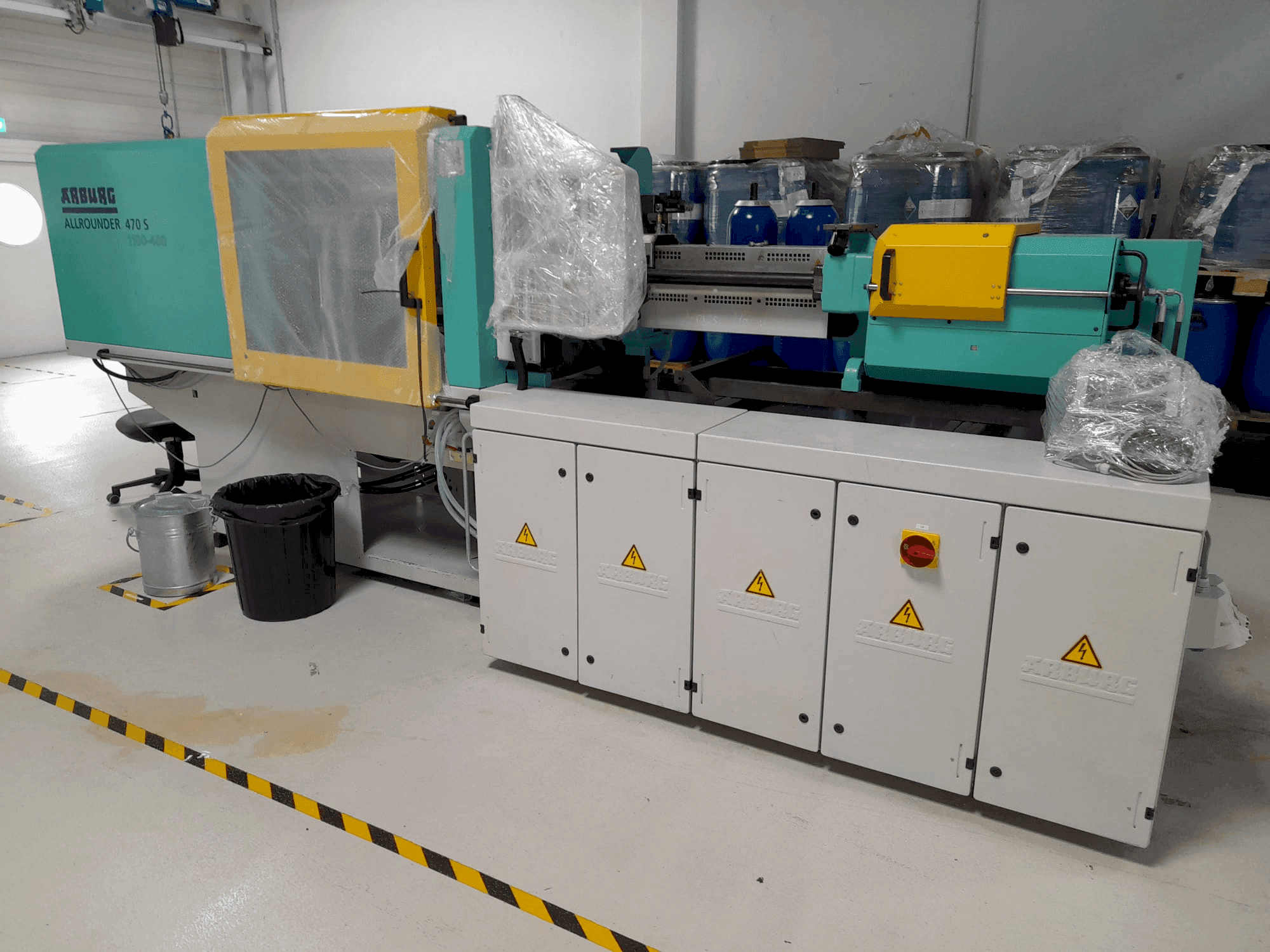

Arburg - Allrounder 470S 1100-400 with Multilift handlingDE-INJ-ARB-2010-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Plastics Processing Machinery

- ARBURG Allrounder 470S 1100-400 with Multilift handling Injection moulding machine

This ARBURG Allrounder 470S 1100-400 with Multilift handling Injection moulding machine was manufactured in the year 2010 and has 63300 pump operating hours. It is equipped with a two blow-out devices with pressure reducer. The machine has a MULTILIFT V SELECT type (cross-mounted on the machine, 3 CNC axes, freely programmable, axes can be moved simultaneously, drive via servo motors). Disposes of a protective housing Bosch profile with wave grille, access door electrically protected

Overview

- brand: Arburg

- year: 2010

- MODEL: Allrounder 470S 1100-400 with Multilift handling

- production hours: 63300

- application type: Injection Moulding

- Location: Germany

- machine type: Hydraulic Injection Moulding Machine

Technical Information - Arburg Allrounder 470S 1100-400 with Multilift handling

Dimensions

- Machine Depth: 4500 mm

- Machine Height: 3000 mm

- Machine Weight: 4800 kg

Additional Information

Machine Benefits

Qualitative Machine Benefits

- Multilift v select (cross-mounted on the machine, 3 cnc axes, freely programmable, axes can be moved simultaneously, drive via servo motors)

- Technology level 2 with two control pumps for controlled machine movements

- Protective housing bosch profile with wave grille, access door electrically protected

- 16 freely programmable inputs

- 16 freely programmable outputs

- Temperature in the control cabinet controlled by water cooling

- Special process extended guard locking

- 9 electrical heating control circuits for mold heating (hot runner) sensor type j

Technical Machine Benefits

- Locking device: 1100 kn // voltage: 400 v / 50 hz // motor / heating back-up fuse: 125 a // max. Injection volume: 154 ccm

- Position-controlled screw // pressure accumulator for high pressures / speed

- Plasticizing cylinder 35 mm highly wear and corrosion resistant, max. Processing temperature 450° b9ksppti8d // piezo charge amplifier for internal pressure measurement

- Programmable nozzle contact force // centering diameter nozzle side: 125 mm

- Ejector with quick-release coupling // ejector stroke max. : 175 mm mold height min. : 300 mm // maximum platen distance: 950 mm // column spacing: 470 x 470 mm

- Printer interface // temperature control unit interface 20ma max. 6 devices // allrounder at web interface // interface for coloring / dosing device // interface for mold monitoring through ejector plate safety device

- Machine cycles: 4,649,834 h // pump operating hours: 63,300 // operating hours car: 57,584

- Axis lengths, axis speed: z-axis (transverse to the longitudinal machine axis) 1400 mm ---- mm/s // x-axis (parallel to the longitudinal machine axis) 400 mm --- mm/s // z-axis (plunge axis) 600 mm ---- mm/s // c-axis pneumatic folding axis

- Deposit height: 1100 +/- 200 mm

- 4 x pneumatic valves 5/3 with locked center position for gripper functions - 4 x vacuum equipment incl. Vacuum switch for parts monitoring

Extra Information

Two blow-out devices with pressure reducer // Three freely programmable core pulls // Off-line filtering

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing