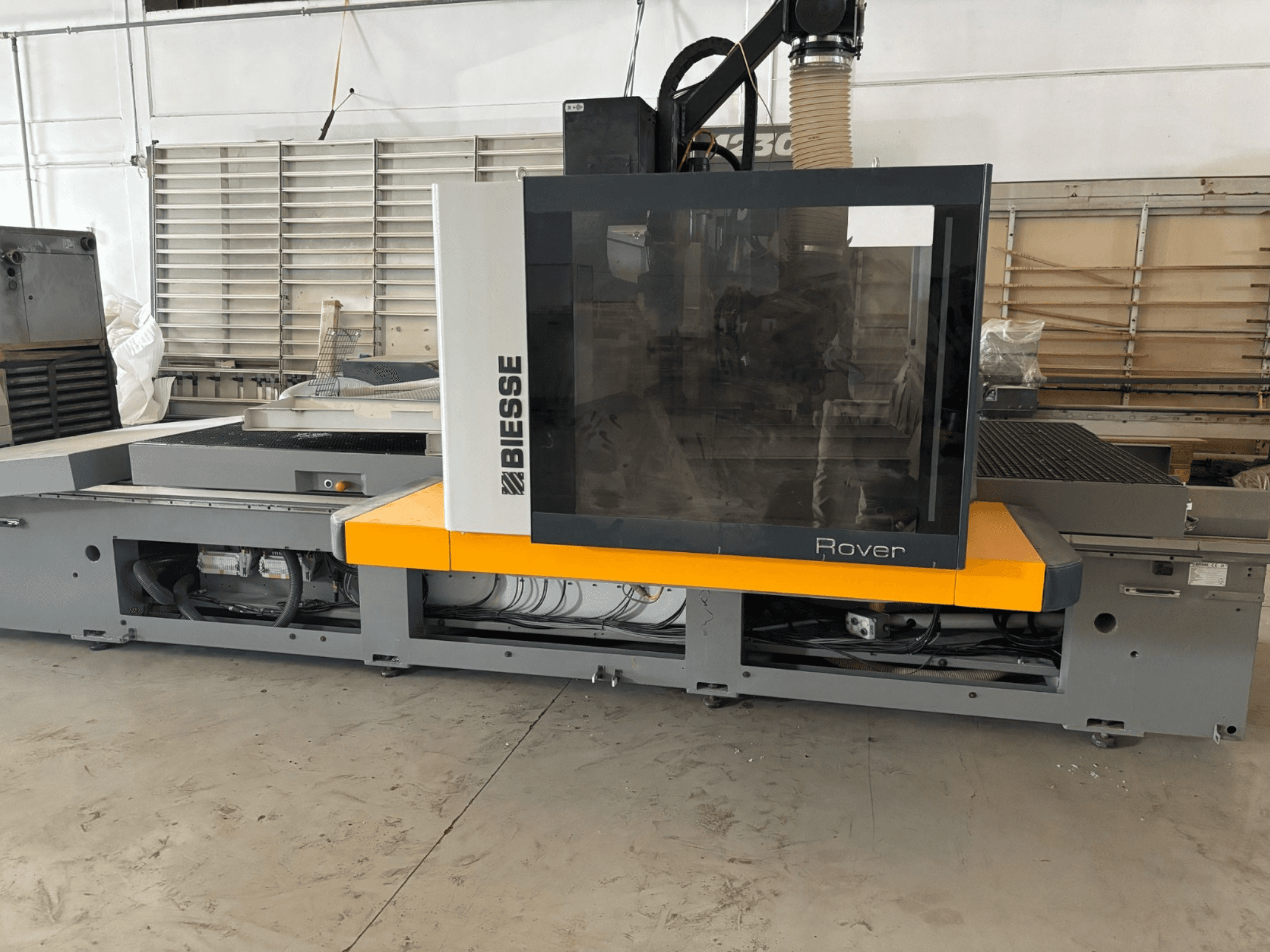

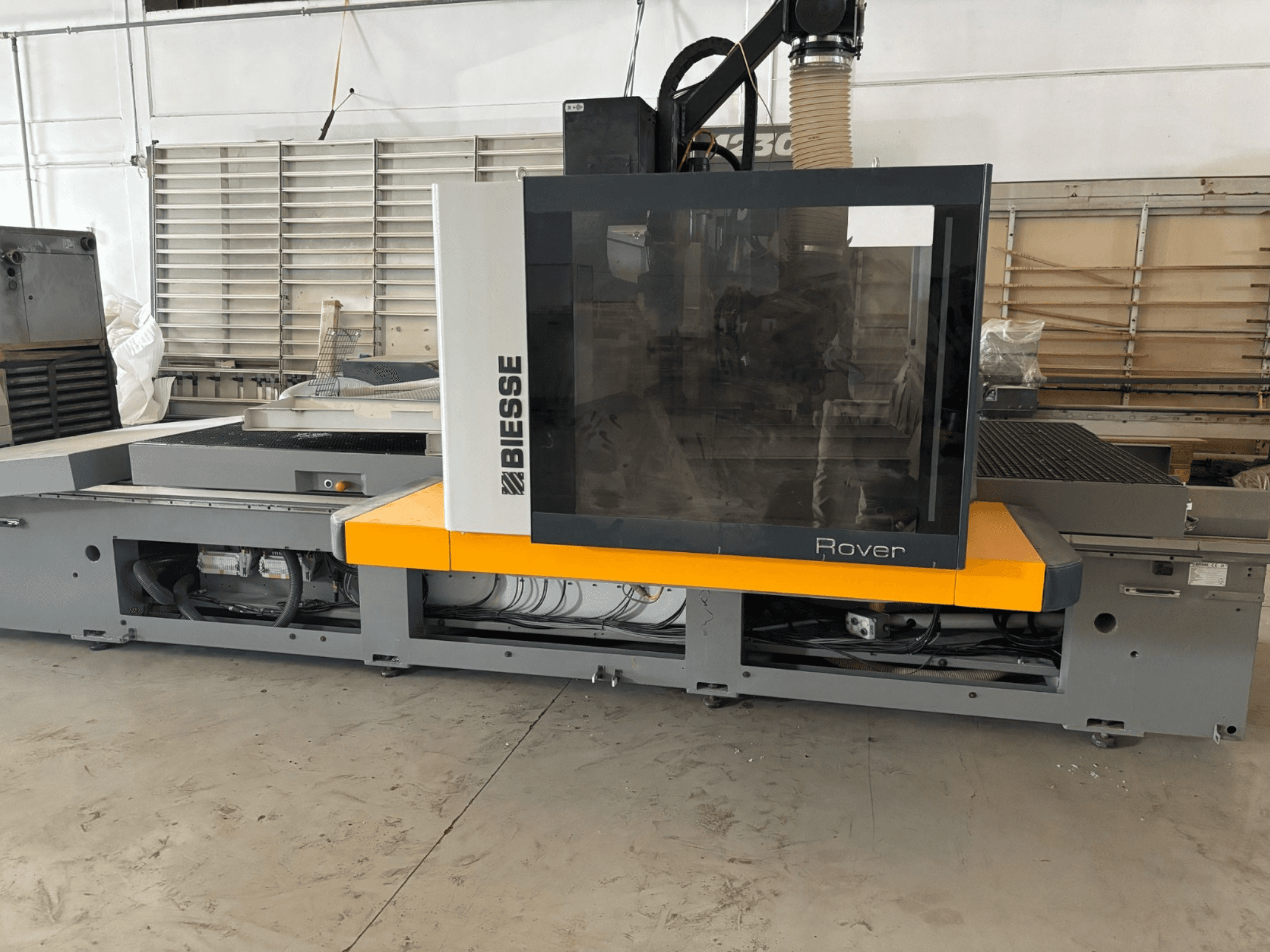

BIESSE - Rover PLAST A FT 1536ES-CNC-BIE-2020-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Wood Working

- ➤ Used BIESSE Rover PLAST A FT 1536 | For Sale

This 5-axis BIESSE Rover PLAST A FT 1536 was manufactured in 2020, featuring a robust electro-welded base and high-precision movement systems. It boasts a main electrospindle power of 13.2 kW, a programmable rotation speed up to 24,000 RPM, and an 8-position revolver tool magazine. Ideal for intricate woodworking, it includes a 21.5" LCD monitor and Industry 4.0 integration. Consider the opportunity to buy this BIESSE Rover PLAST A FT 1536 CNC Wood Machining Centre. Contact us for more information.

Overview

- brand: BIESSE

- year: 2020

- MODEL: Rover PLAST A FT 1536

- application type: CNC Wood Machining

- Location: Spain

- machine type: CNC Wood Machining Centre

Technical Information - BIESSE Rover PLAST A FT 1536

Movement

- Number of Axes: 3

- X-axis Travel: 3765 mm

- Y-axis Travel: 1560 mm

- Z-axis Travel: 378 mm

Technical Specification

- Spindle Power: 13.2 kW

- Spindle Speed: 24000 RPM

Additional Information

Maximum piece clearance: 170 mm

Axis speeds: X 85 m/min, Y 60 m/min, Z 20 m/min

Base: Electro-welded closed-circuit structure with high-thickness steel plates

Axis drives: X with two independent brushless motors and helical rack & pinion; Z with preloaded ballscrew, ISO5 precision

Work table: Phenolic laminate with 30 mm grid vacuum system; vacuum steps every 150 mm; M8 threaded inserts for templates/fixtures

Main electrospindle: 13.2 kW (17.7 HP), HSK F63, air-cooled, 1,000–24,000 rpm

Tool magazine: 8-position revolver on Y-carriage; max tool diameter 110 mm; max tool weight 7.5 kg (32 kg total magazine)

Tool measurement: Digital presetter for tool length measurement up to 130 mm diameter

Control system: BH660 PC-based with Windows Real Time (WRT); CPU Intel Core i5 or better; 8 GB RAM; 128 GB SSD or better; 21.5" LCD monitor

Power supply: 380/400/415 V, 50/60 Hz

Automatic lubrication system for moving parts

Software: bSolid 3D CAD-CAM for design, simulation, and process management

Connectivity: Industry 4.0 integration via TCP/IP and OPC-UA

Additional equipment

Vacuum pump: 250 m³/h, dry-running

Air conditioner for the electrical cabinet

Safety guarding: 2 m high protection nets and front vertical photocells

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing