Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

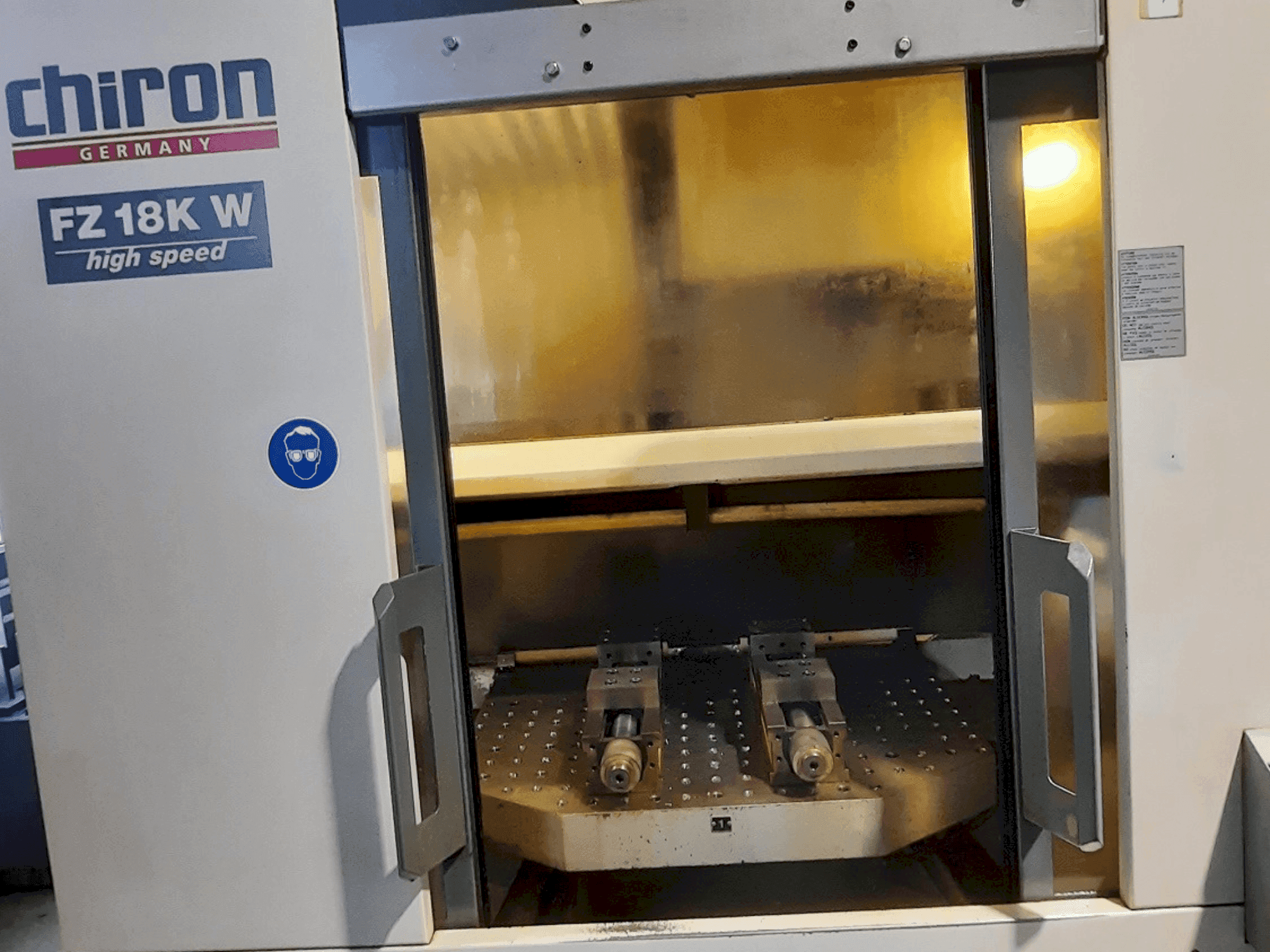

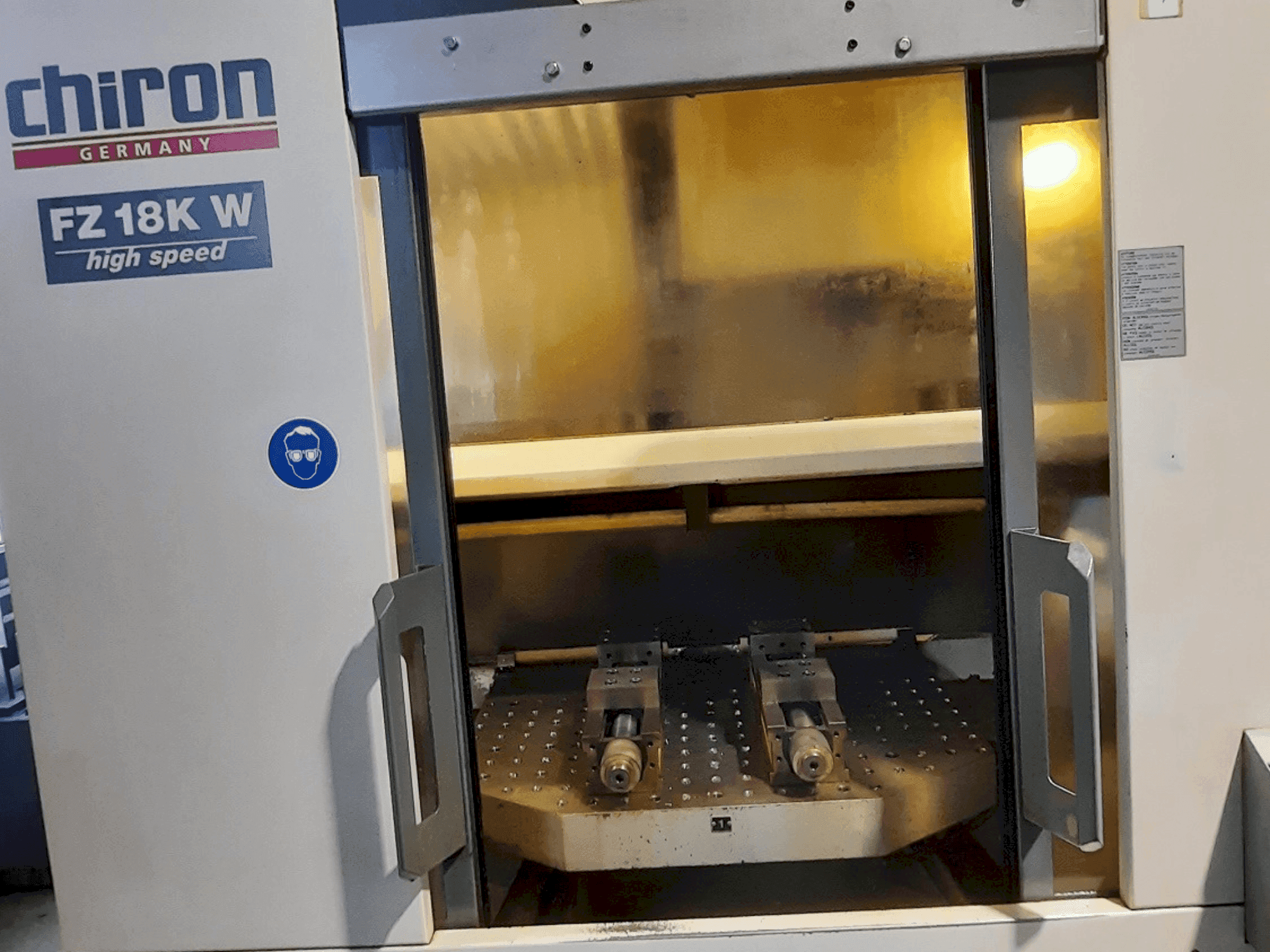

CHIRON - FZ 18 KWDE-MIL-CHI-2001-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used CHIRON FZ 18 KW For Sale | gindumac.com

This 3-axis CHIRON FZ 18 KW vertical machining center was manufactured in 2001. It features a robust AC motor with a speed range of 20-10,500 rpm and a drilling capacity of 42 mm. The machine includes a 40-position automatic tool changer and a rapid traverse speed of 40 m/min in all axes. It's equipped with a Siemens CNC control 840D, ensuring precise and efficient operations. Consider the opportunity to buy this CHIRON FZ 18 KW vertical machining center. Contact us for more information.

Overview

- brand: CHIRON

- year: 2001

- MODEL: FZ 18 KW

- application type: Milling

- Location: Germany

- machine type: Vertical Machining Centre

- control unit brand: SIEMENS

Technical Information - CHIRON FZ 18 KW

Control Unit

- Control Brand: SIEMENS

- Control Model: 840D

Movement

- Number of Axes: 3

- X-axis Travel: 630 mm

- Y-axis Travel: 400 mm

- Z-axis Travel: 630 mm

Technical Specification

- Max. Tool Weight: 5 kg

- Spindle Power: 10 kW

- Spindle Speed: 10500 RPM

Additional Information

Machine Benefits

Technical Machine Benefits

- Main spindle drive with ac motor

- Power: 10 kw at 100% duty cycle, 18 kw at 25% duty cycle

- Feed drive for x, y, and z axes with digital direct drives and indirect absolute position measuring system

- Acceleration: 0. 5 g in the x and y axes, 0. 7 g in the z axis

- Transport load per side: 0 - max 400 kg

- Workpiece changing device with stainless steel center divider

- Workpiece change time: approx. 3. 7 s (weight-dependent, self-regulating)

Extra Information

Tools Automatic tool changer with 40 tool positions Tool shank: steep taper 40 DIN 69871+72 Tool diameter with free adjacent positions: 160 mm Tool change time: approx. 1.0 s (control-dependent) Chip-to-chip time: approx. 2.9 s (control-dependent) Control Unit SIEMENS CNC control 840D Includes 10.4" TFT color screen and full keyboard OP032S NC RAM 256 KB (freely available max. 200 programs) Features: Drilling cycles G81-G89, Drilling and milling patterns, M and T functions, Circular interpolation, Program restart, Subroutine technology, Simultaneous programming, Contour train programming, Cycle support, Polar coordinates, Tool compensation for geometry and wear, Tool radius compensation, 3D interpolation, Mirroring, Scale factor, Chamfers and radii insertion, RS 232C interface, Oriented spindle stop, Execution of large CNC programs, Software limit switches, NC diagnostics, Absolute position measuring systems, Power display on screen, Revolutional feedrate look-ahead

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing