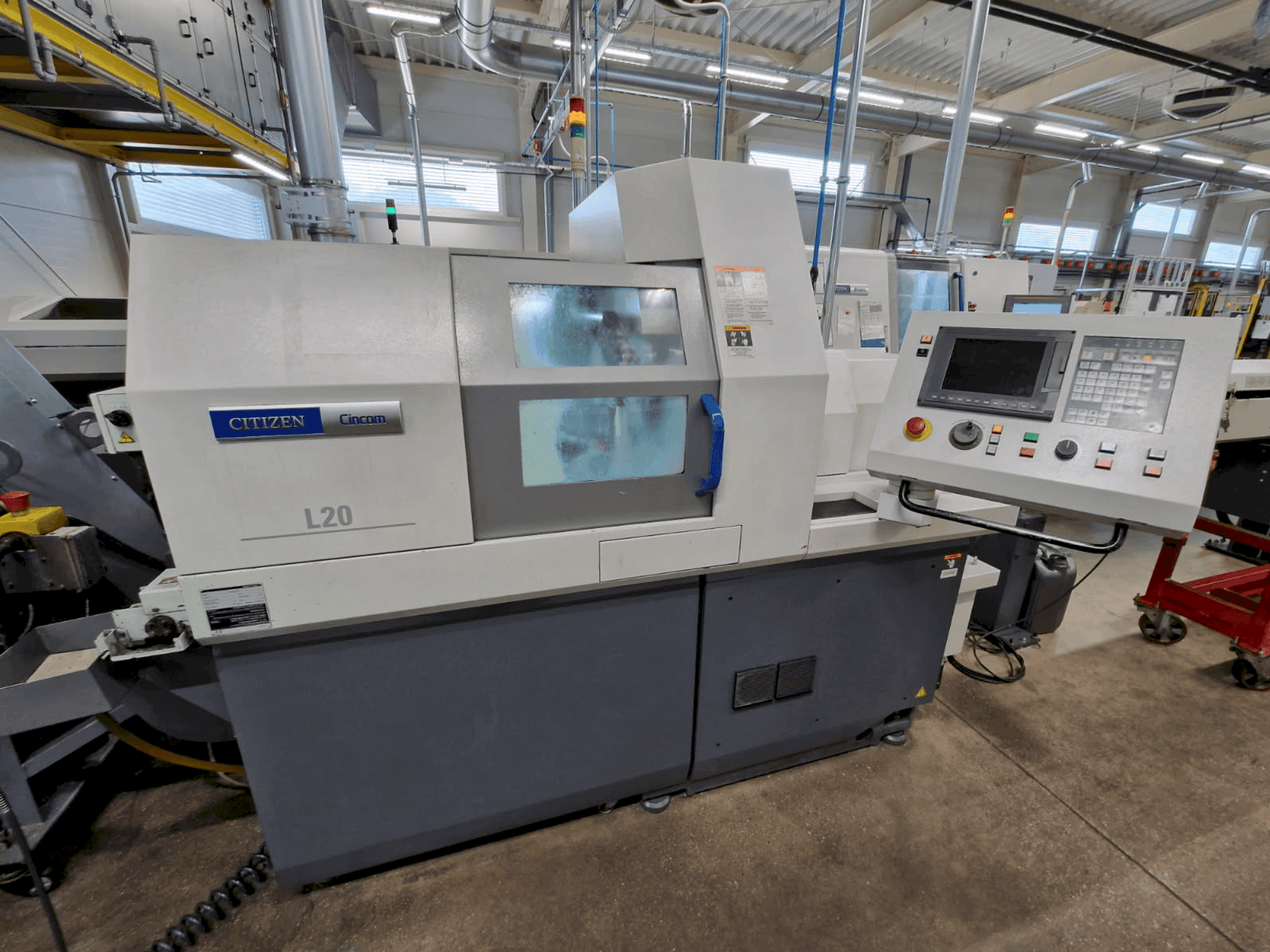

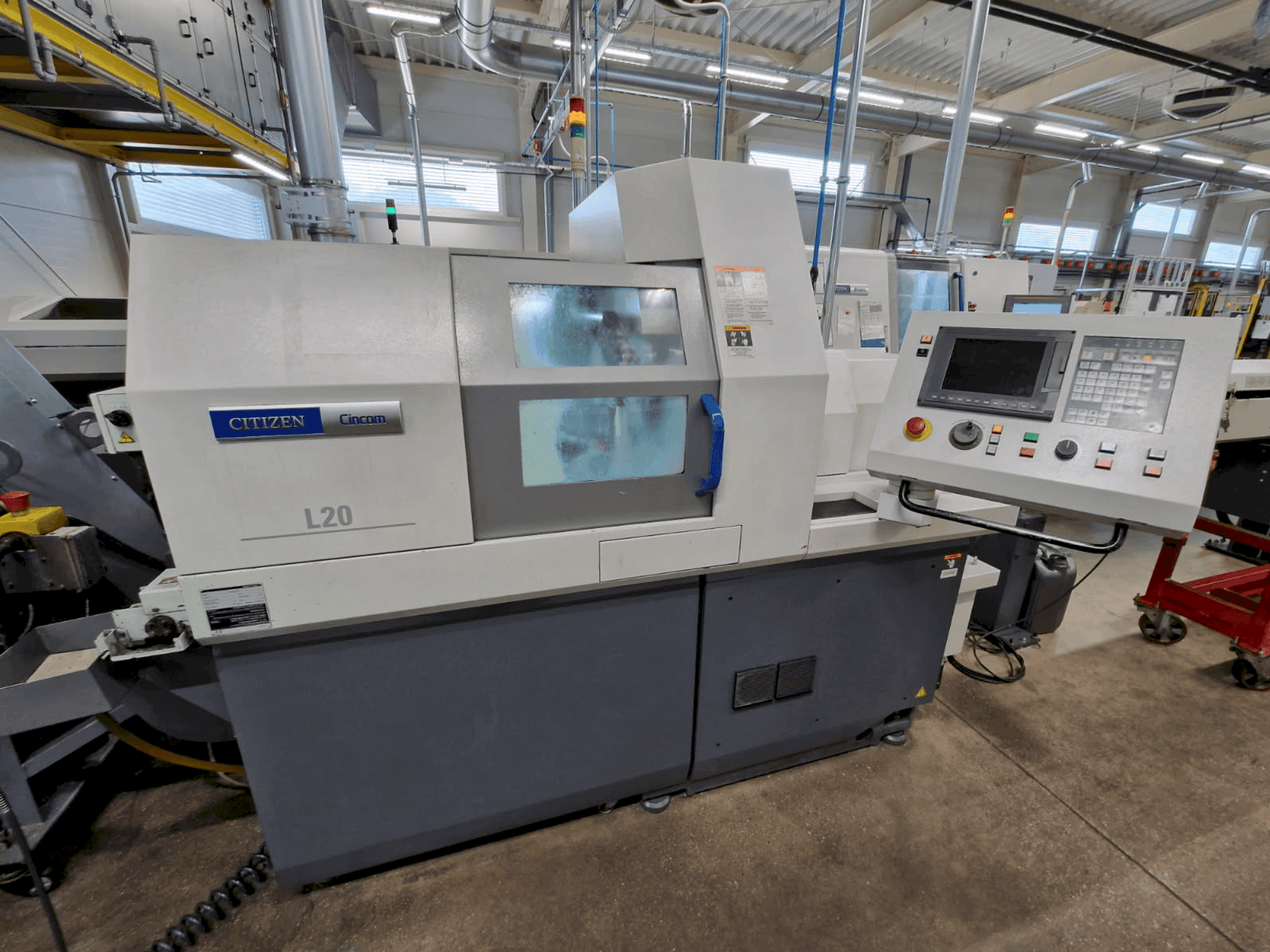

Citizen - Cincom L20E-2M8SI-TUR-CIT-2016-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used Citizen CITIZEN Cincom L20E-2M8 | Swiss Type Lathe

This 8-axis Citizen Cincom L20E-2M8 was manufactured in 2016, designed for precision Swiss-type turning come with FMB bar feeder and LNS chip conveyor. It features a main spindle with a speed of up to 10,000 rpm and a counter spindle operating at 8,000 rpm. The machine accommodates up to 37 tools, enhancing its capability for complex machining tasks. It includes a Mitsubishi Meldas 700 controller for efficient operation. Consider the opportunity to buy this Citizen Cincom L20E-2M8 Swiss type turning machine. Contact us for more information.

Overview

- brand: Citizen

- year: 2016

- MODEL: Cincom L20E-2M8

- application type: Turning

- Location: Slovenia

- machine type: Swiss Type Turning Machine

- control unit brand: MITSUBISHI

Technical Information - Citizen Cincom L20E-2M8

Control Unit

- Control Brand: MITSUBISHI

- Control Model: Meldas 700

Dimensions

- Machine Depth: 2300 mm

- Machine Height: 1835 mm

- Machine Weight: 2220 kg

Additional Information

CITIZEN Cincom L20E-2M8 with FMB Bar feeder and LNS chip conveyor

The machine is suitable for efficient turning up to 20 mm in diameter.

The machine is designed to accommodate up to 37 tools for machining complex products.

Tool sub-assemblies set:

Vertical holder with 5 tools

4–7 rotating tools for transverse radial machining

Drilling tools 3–9 for front machining

0–4 rotating tools for counter spindle

4–10 drilling tools for counter spindle

Basic configuration

Basic bed: block casting with strong linear guides (thermal and vibration stability)

Main spindle: 10,000 rpm, C-axis, Ø passage 26 mm (max. bar Ø20 mm)

W1: vertical holder with 5 tools (12 × 12 × 130 mm)

3× GSC1310 radial rotating tools ER16 (1 kW, 7,500 rpm)

GSE3210 rotating unit adjustable 0°/90° for milling unit (3× GSC1310 ER16)

U124B drilling block (2+1) for deep holes

Counter spindle: 8,000 rpm, optional C-axis, power 0.75/1.5 kW

U153B driven tool unit for counter spindle (0.75 kW) + 4× SAU819 adapters Ø19.05

Controller: Mitsubishi Meldas 700 (Windows OS, improved processor, LCD 8.4")

Simultaneous machining on main and auxiliary spindles

New sliding door cover design, space-saving

Technical data

Main spindle

Max. turning length: 200 mm

Throughput Ø: 26 mm

Max. bar Ø: 20 mm

Speed: 200–10,000 rpm

Power: 2.2 / 3.7 kW

Positioning: C-axis (0.001°)

Counter spindle

Max. bar Ø: 20 mm

Speed: 200–8,000 rpm

Power: 0.75 / 1.5 kW

Positioning: C-axis

Max. workpiece length in collet: 80 mm

Driven tools

Speed: 200–7,500 rpm

Power: 1 kW

5 tools (vertical holder) + 4–7 radial + 3 in Z-direction

Tools

5 tools (12 × 12 × 130 mm)

3-position drilling block on counter spindle (3× Ø25.4 mm)

Back machining holders: 3–6 (Ø19.06 mm)

Guides

Collets: E145

Guide bushing: Neukomm 22.001

Machine ER16 / ER11

Additional equipment

Clamping unit Ø25 mm

Pump 15 bar for rinsing the counterspindle

SAU819 adapters up to Ø8 mm

Transformer 3×400V/3×200V, 10 kW

Swarf conveyor LNS MH-HB

FMB Minimag 20/3200 bar feeder

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing