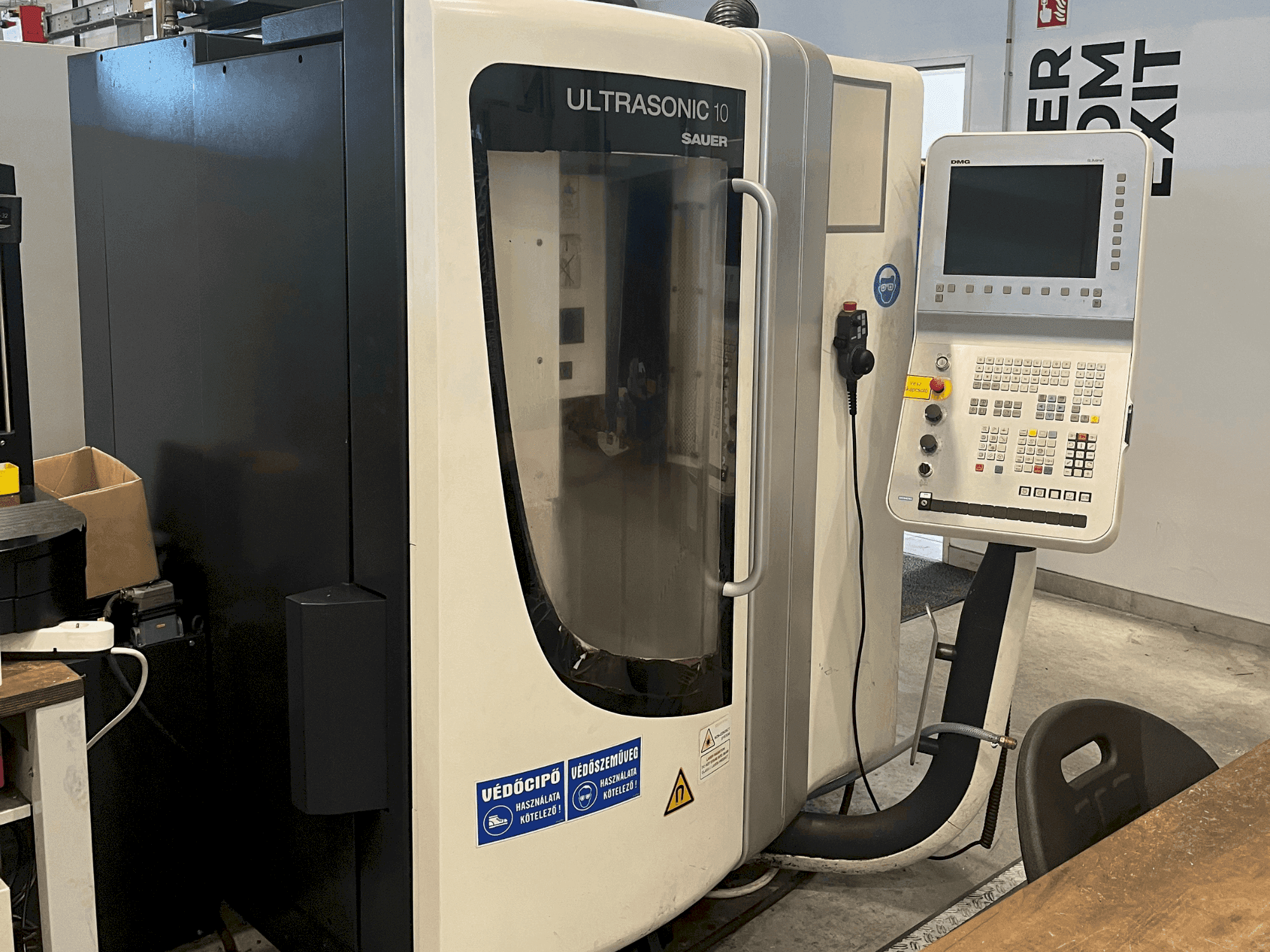

DMG - ULTRASONIC 10HU-MIL-DMG-2011-00003

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used DMG ULTRASONIC 10 For Sale | gindumac.com

This 5-axis DMG ULTRASONIC 10 was manufactured in 2011. It features a Siemens Sinumeric 840D control, a spindle with 40,000 rpm max speed, and a tool magazine with 60 slots. The machine offers a compact footprint and includes options like a DMG PP-400 Infrared probe and RS NC-4 tool measurement. If you are looking to get high-quality milling capabilities consider the DMG ULTRASONIC 10 machine we have for sale. Contact us for more information about this machine.

Overview

- brand: DMG

- year: 2011

- MODEL: ULTRASONIC 10

- production hours: 937

- application type: Milling

- Location: Hungary

- machine type: Vertical Machining Centre

- control unit brand: SIEMENS

Technical Information - DMG ULTRASONIC 10

Control Unit

- Control Brand: SIEMENS

- Control Model: Sinumeric 840D

Dimensions

- Machine Depth: 775 mm

- Machine Height: 2253 mm

- Machine Weight: 1800 kg

- Table Load: 10 kg

Movement

- Number of Axes: 5

- X-axis Travel: 120 mm

- Y-axis Travel: 120 mm

- Z-axis Travel: 200 mm

Technical Specification

- Spindle Speed: 40000 RPM

Additional Information

Additional equipment

- Workpiece Measurement: DMG PP-400 Infrared probe

- Tool Measurement: RS NC-4

- Coolant Conditioning Equipment: KM 10

Machine Benefits

Technical Machine Benefits

- Surface area: less than 2 m²

- Required space (lxwxh): 4100x3700x2300 mm

- Machine on time: 2773 hours

- A axis: -10° to 120°

- C axis: 360°

- Feedrate – feed speed range: up to 10000 mm/min

- Repeatability in x / y / z: p8 μm

Extra Information

Workpiece NC Table with Clamping Surface: ø 190 mm Max.Speed of Rotary Axes (A / C): 100 rpm / 150 rpm Positioning Accuracy (A / C Axis): ± 5 Tools Tool Magazine: 60 items, chain magazine Chip-to-Chip Replacement Time: 15 seconds Media Compressed Air Required: 6 bar Average Air Consumption: 20 m³/hour Working Voltage: 400V (N / PE) / 50A

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing