Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

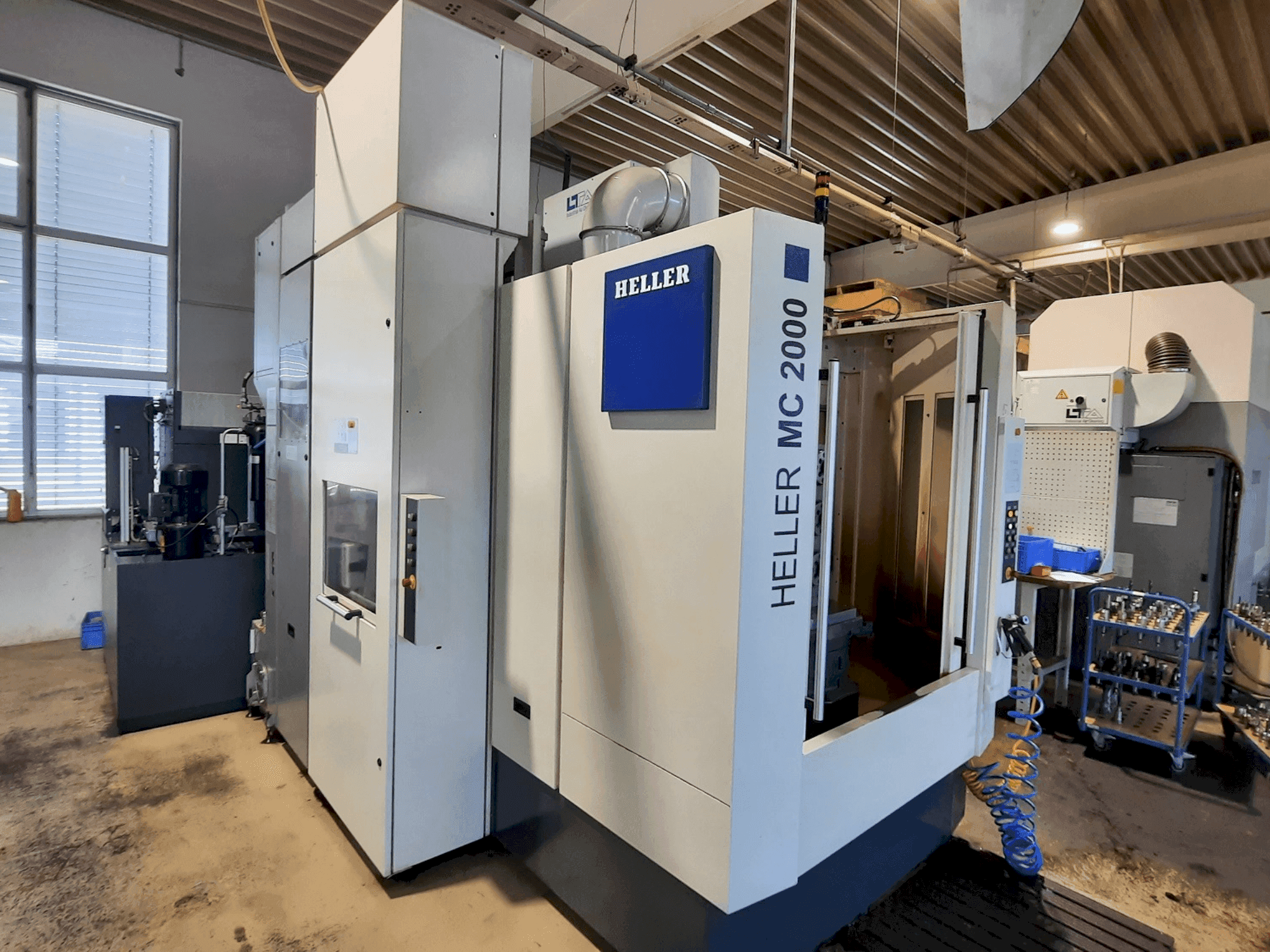

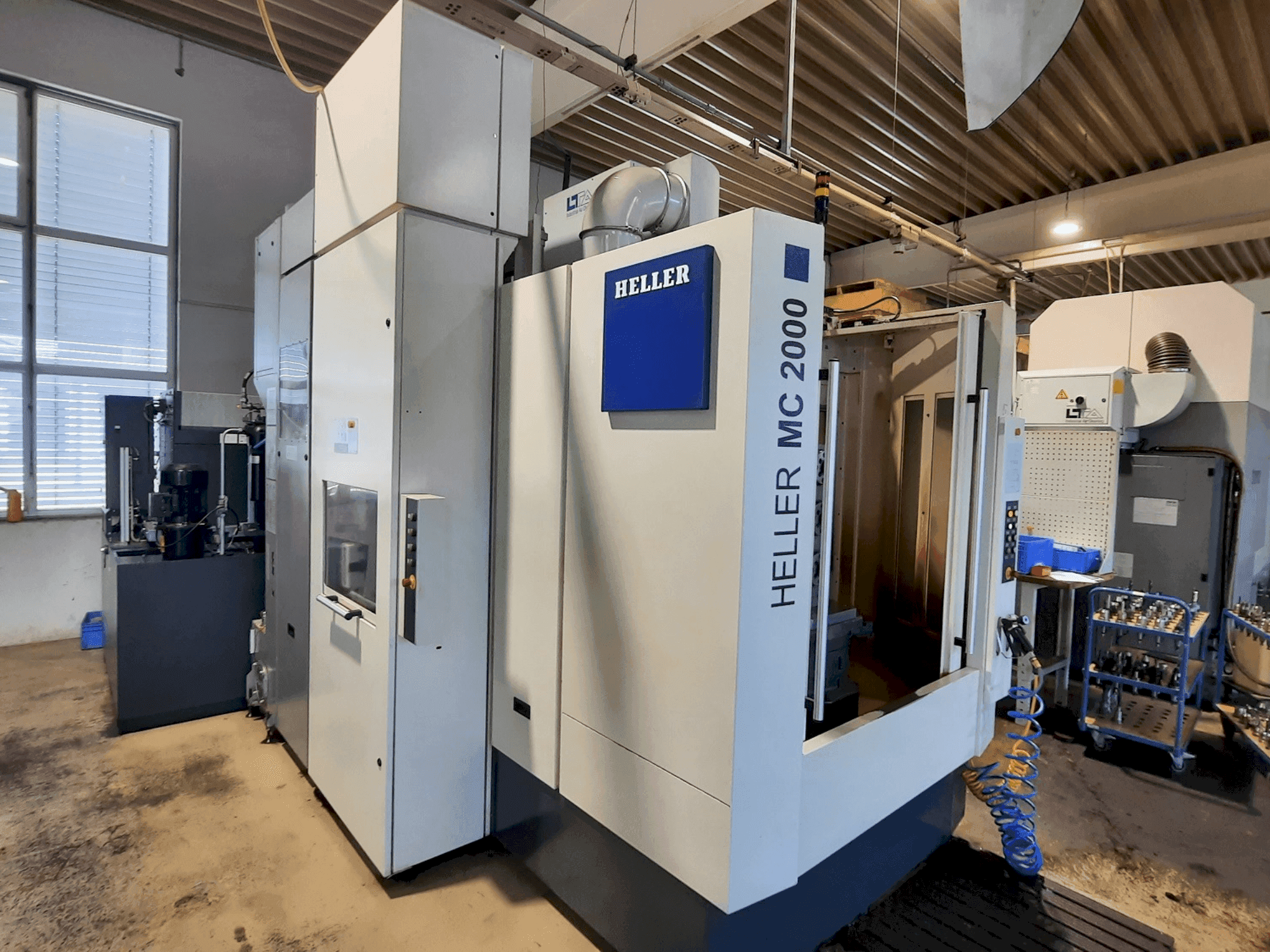

HELLER - MC 2000DE-MIL-HEL-2011-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used HELLER MC 2000 For Sale | gindumac.com

This 3-axis HELLER MC 2000 was manufactured in 2011 and features a robust three-phase motor spindle, delivering 17 kW at 10,000 rpm with a SK 40 tool holder. It includes a 2-axis servo tool changer, a stationary tool magazine with 54 positions, and a pallet changing device with 2 pallet positions. If you are looking to get high-quality milling capabilities, consider the HELLER MC 2000 machine we have for sale. Contact us for more information about this machine.

Overview

- brand: HELLER

- year: 2011

- MODEL: MC 2000

- application type: Milling

- Location: Germany

- machine type: Horizontal Machining Centre

- control unit brand: SIEMENS

Technical Information - HELLER MC 2000

Control Unit

- Control Brand: SIEMENS

Movement

- Number of Axes: 3

Technical Specification

- Spindle Power: 17 kW

- Spindle Speed: 10000 RPM

Additional Information

Additional equipment

- Scraper belt conveyor for dry machining

- Cold light in the work area

- Central cooling unit for motor spindle and control cabinet, CFC-free

Machine Benefits

Technical Machine Benefits

- Central cooling unit for motor spindle and control cabinet, cfc-free

- Design according to ce standards

- Paint finish: gray-white / anthracite gray / dust gray / heller red

- Control cabinet with integrated control, regulation, and power unit

- Operating voltage 400v / 50hz, voltage range +/- 10% // control voltage 24v dc

- Increased spindle power with power cutting at 240 nm

- Axis dynamic power

- Full machine enclosure including cover

- Automatic central lubrication

- Hydraulic system

Extra Information

Operating instructions include: Operating instructions Control-specific documents Maintenance instructions Spare and wear parts list Supplier instructions Fluid diagrams and electrical diagrams Three-phase motor spindle package with hollow shaft motor, 17 kW at 40% duty cycle, 10000 rpm in asynchronous technology, SK 40 tool holder according to DIN 69 871, Form A, AD and B, for pull studs according to DIN 69872 Form A and B Adjustable, maintenance-free three-phase feed drives Direct position measuring system in the X, Y, Z, and B axes Movement 2-axis servo tool changer Stationary tool magazine with 54 tool positions and fixed position coding Control panel at the workpiece setup station NC rotary table with 360000 x 0.001° pitch Pallet changing device with 2 pallet positions Workpiece Setup station, manually rotatable 4 x 90° The machine has been measured.

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing