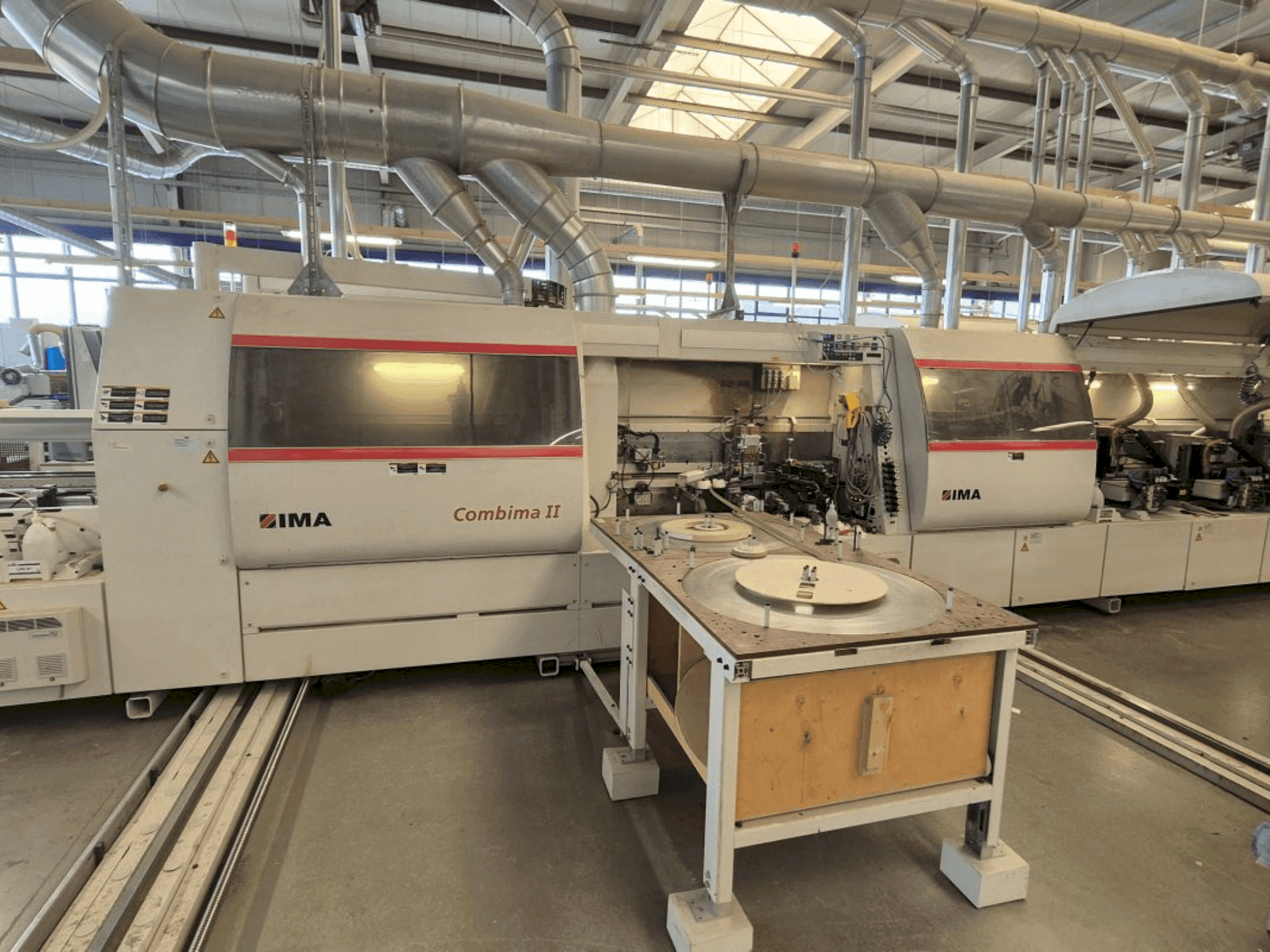

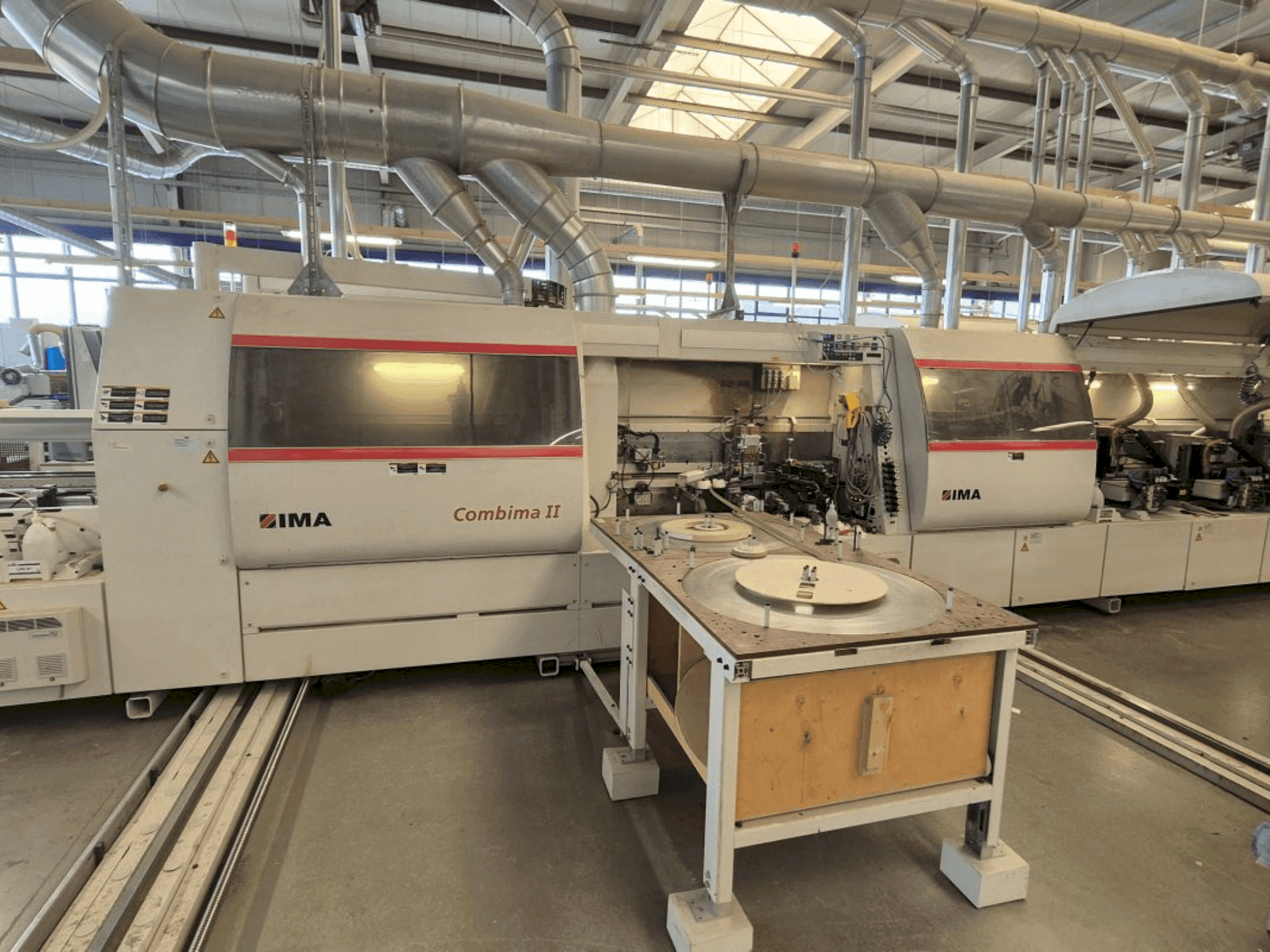

IMA - Combima/II/390/B/L12DE-EDG-IMA-2010-00002

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Wood Working

- ➤ Used IMA Combima/II/390/B/L12 For Sale | gindumac.com

This IMA Combima/II/390/B/L12 was manufactured in 2010. A robust double-sided edgebander, it features a max feed width of 3,300 mm and handles workpiece thicknesses up to 60 mm. Equipped with ICOS OPEN control for precision, it supports both roll and strip edgebanding materials. Ideal for high-capacity environments requiring flexibility and reliability in edge finishing. Contact us for more information about this machine.

Overview

- brand: IMA

- year: 2010

- MODEL: Combima/II/390/B/L12

- application type: Edge Banding

- Location: Germany

- machine type: Double Sided Edgebander

Additional Information

Additional equipment

- Gluing Unit for Hot-Melt Adhesive: Single roll/strip magazine for roll material up to 3 mm and strips up to 12 mm

- End Trimming Unit: 2 motors, each 660 W, pneumatic swiveling 0° + 25°

Machine Benefits

Technical Machine Benefits

- Min. Feed width: 244 mm (in longitudinal processing)

- Max. Feed width: 3300 mm

- Max. Workpiece width (with chain conveyor extension): 1300 mm

- Min. Workpiece thickness: 8 mm

- Max. Workpiece thickness: 45 mm (with copying function) / 60 mm (without copying)

- Max. Feed width: 3300 mm

- Fixed reference side: on the left in feed direction

Extra Information

Scoring Saw: 22 kW motor, 6000 rpm, pneumatically controlled Rough Trimming Unit: 80 kW motor, 6000 rpm Double Milling Unit: 2 motors, each 45 kW, 9000 rpm Flush Milling Unit: 2 motors, 1850 W, 12000 rpm Multifunction Unit: NC-controlled with 2 motors, automatic tooling for 4 profiles Buffing Unit: 2 motors, each 180 W, 1400 rpm Grooving Unit: 45 kW motor, 9000 rpm Control Unit ICOS OPEN: PC-based control system with integrated PLC and electronic path control, user-friendly interface with Windows standards

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing