Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

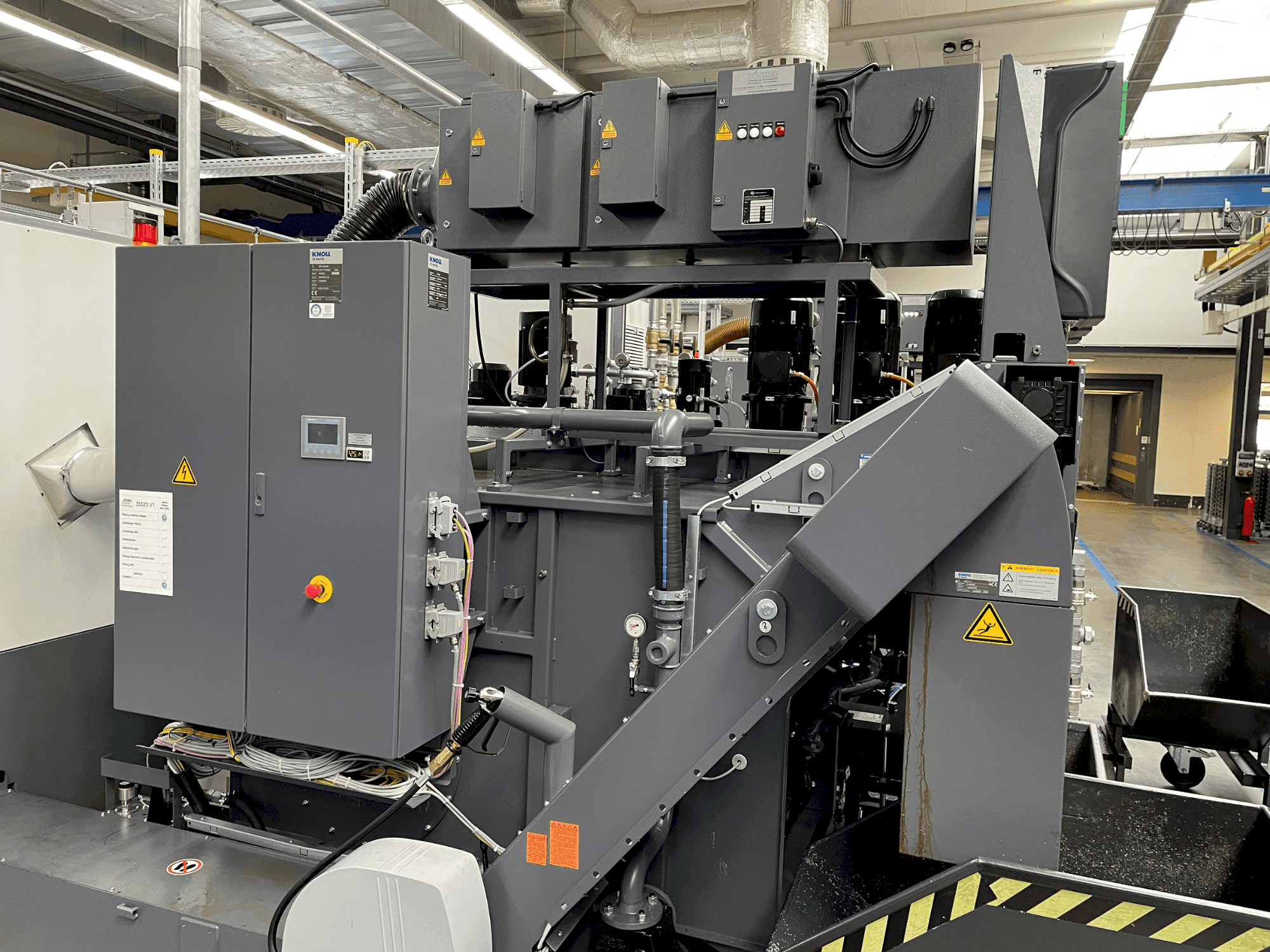

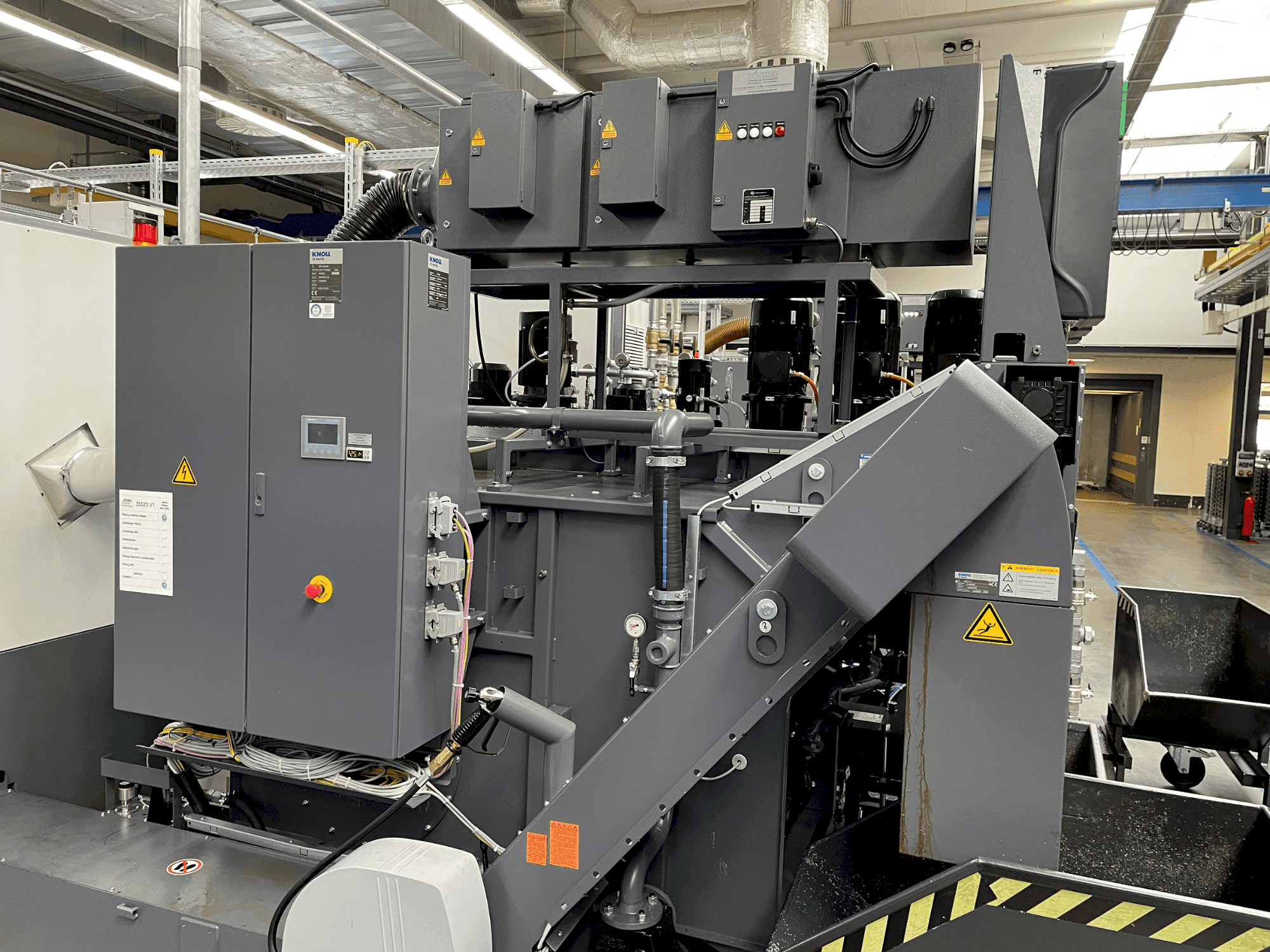

KNOLL - KF 400/3400DE-OTH-KNO-2019-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used KNOLL KF 400/3400 - 2019 - For sale | gindumac.com

This KNOLL KF 400/3400 was manufactured in 2019. It features a scraper belt conveyor and a compact filter system designed for machining processes with specific environmental conditions. The system includes a clean tank with a 3400-liter capacity and a variety of pumps, including a centrifugal process pump and a screw pump, ensuring efficient fluid movement. Ideal for handling cooling lubricant emulsions, it also includes plate heat exchangers for effective cooling. Contact us for more information.

Overview

- brand: KNOLL

- year: 2019

- MODEL: KF 400/3400

- application type: Other Machine Tools

- Location: Germany

- machine type: Machine Tool

Additional Information

Additional equipment

- Scraper belt conveyor type 400 K-1, medium emulsion.

- System compact filter KF type KF400/3400.

- Compact filter KF 400 with position drive/inlet KF right, take-up unit KF yes, fleece holder KF at the rear (externally mounted).

- Clean tank, flat, rectangular shape, dimensions 2500x1500x1100mm, capacity 3400l, material steel, sheet thickness 3mm, tank cover sheet steel.

- Centrifugal pump, process pump function, flow rate 320l/min, pressure 5 bar, submersible version.

- Screw pump KTS 32: HD piston bushing (KB), spindle pitch 48, PTC thermistor and frequency-controlled, flow rate 65l/min and 80 bar pressure.

- Plate heat exchanger 25 plates: dimensions 424x323x670mm, medium to be cooled, cooling capacity 40 kW.

- Plate heat exchanger 15 plates: plate material 1.4404, cooling capacity 16 kW.

- Circulation and PHE supply pump: flow rate 50 litres/min, pressure 5.5 bar.

- Cooling lubricant system for emulsions

Machine Benefits

Qualitative Machine Benefits

- Robust construction, advanced filtration systems.

Technical Machine Benefits

- Comprehensive system designed to support various machining processes with integrated cooling and filtration capabilities.

- High-pressure and high-flow rate pumps ensure efficient handling of cooling and lubrication during operations.

- The system was used for filtering brass shavings, and the level of purity depends on the type of filter fleece used.

Extra Information

Machine still under power

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing