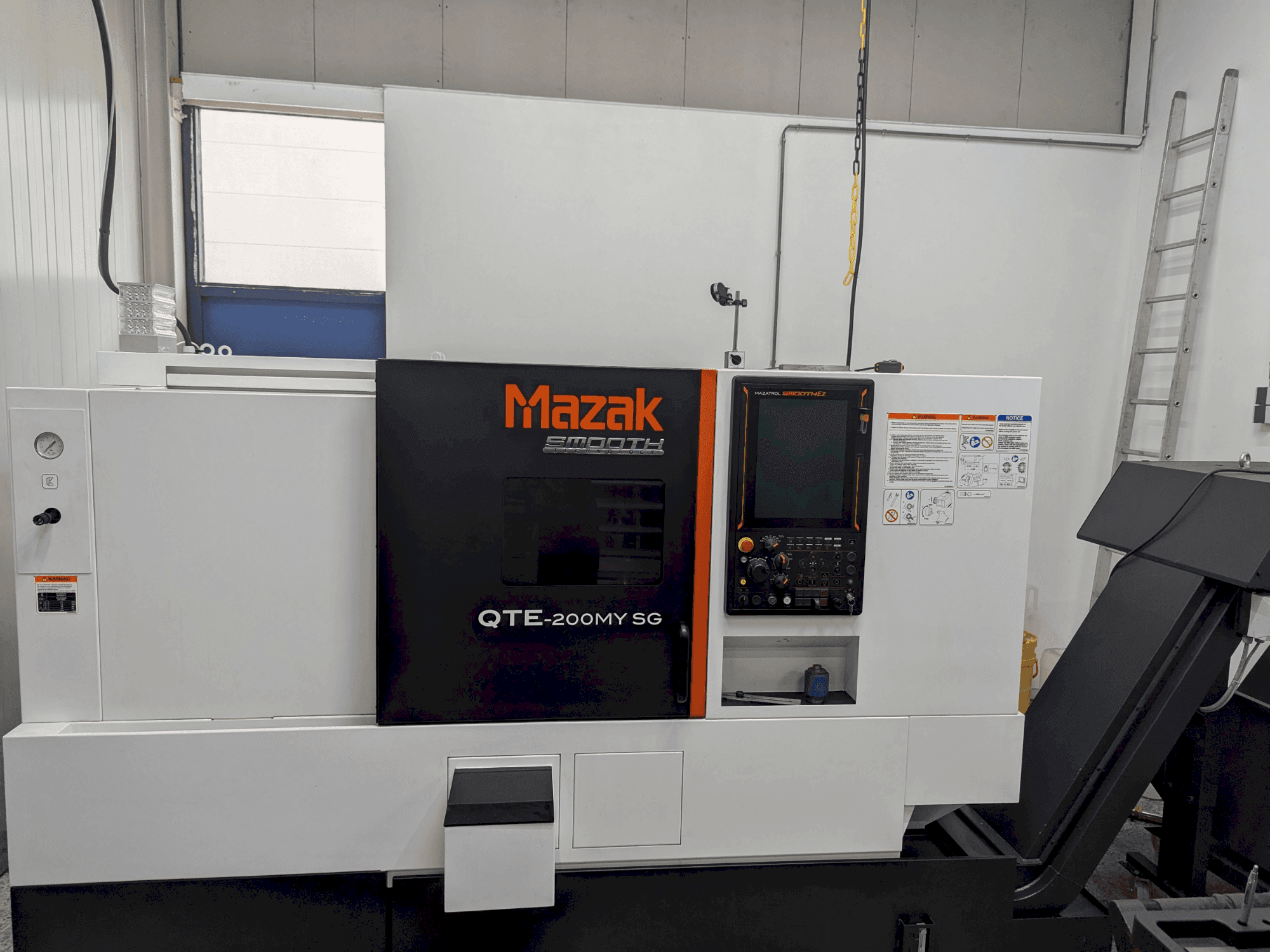

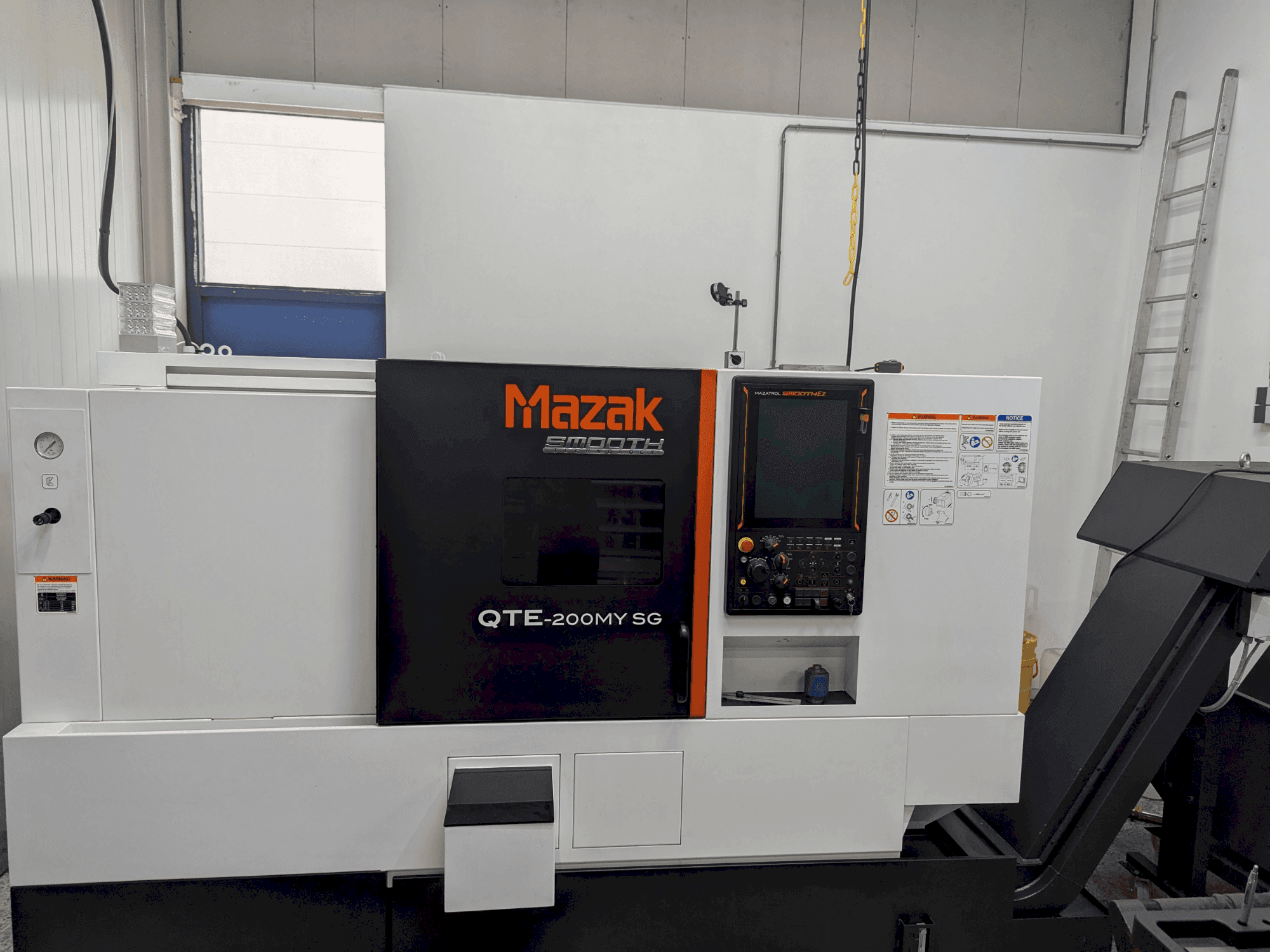

Mazak - QTE-200MY SGNL-TUR-MAZ-2023-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used Mazak QTE-200MY SG For Sale | gindumac.com

This 3-axis Mazak QTE-200MY SG was manufactured in 2023. It features a maximum swing diameter of 695 mm, a standard cutting diameter of 235 mm, and a maximum turning diameter of 340 mm. The main spindle operates at speeds up to 5,000 min-1, with a motor power of 15.0 kW. It includes a 12-position turret and rapid traverse rates on the X, Y, and Z axes are 30, 10, and 30 m/min respectively. Contact us for more information about this machine.

Overview

- brand: Mazak

- year: 2023

- MODEL: QTE-200MY SG

- production hours: 154

- application type: Turning

- Location: Netherlands

- machine type: Horizontal Turning Machine

- control unit brand: MAZATROL

Technical Information - Mazak QTE-200MY SG

Control Unit

- Control Brand: MAZATROL

- Control Model: SMOOTH Ez

Dimensions

- Machine Depth: 2785 mm

- Machine Height: 1725 mm

- Machine Weight: 4650 kg

- Machine Width: 1690 mm

Movement

- Number of Axes: 3

- X-axis Travel: 215 mm

- Y-axis Travel: 100 mm

- Z-axis Travel: 605 mm

Additional Information

Additional equipment

- Transformer for Europe (CE)

- Roller guide with spherical roller bearings

- SD memory card I/F + USB memory I/F

- 1 Set of control keys

- Foundation kit (steel plates)

- CE Marking (With noise filter)

- C-axis Positioning 0.0001° Increment

- 12-Position Turret

- Y-Axis Control

- Interface bar feeder

Extra Information

Automatic part trapper High pressure cooling Preparation for chip conveyor 8" Open chuck Measuring arm Signal tower Rotary center Chain chip conveyor with side discharge Cylindrical and polar coordinate engraving function Automatic pecking cycle with load detection Quick-change cutter holder system Bar diameter Workpiece Maximum swing diameter: 695 mm Standard cutting diameter: 235 mm Maximum cutting length: 535 mm Maximum turning diameter: 340 mm Maximum bar diameter: 65 mm Maximum chuck weight: 200 kg Maximum workpiece weight: 500 kg Distance between spindle nose and end of workpiece: 81 to 686 mm Turret Number of tool positions: 12 Tool size (External turning): 25 mm Tool size (Internal turning): 40 mm Tool size (Driven drill): 20 mm Tool size (Driven end mill): 20 mm Tool size (Driven tap): M20 Indexing time 1 step: 0.23 s Indexing time full revolution: 0.63 s Tail Stock Center bore (morse taper): MK No. 5 Tailstock travel (body movement): 565 mm Maximum thrust: 5000 N Tools Milling spindle power (continuous power): 3.7 kW Milling spindle power (40% ED): 5.5 kW Maximum milling spindle speed: 4500 min-1 Minimum milling spindle speed: 20 min-1 Media Tank capacity: 225 L Coolant pump: MTA70H-250 Power: 0.25 kW Compressed air flow rate: 75 to 370 L/min (ANR)

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing