Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

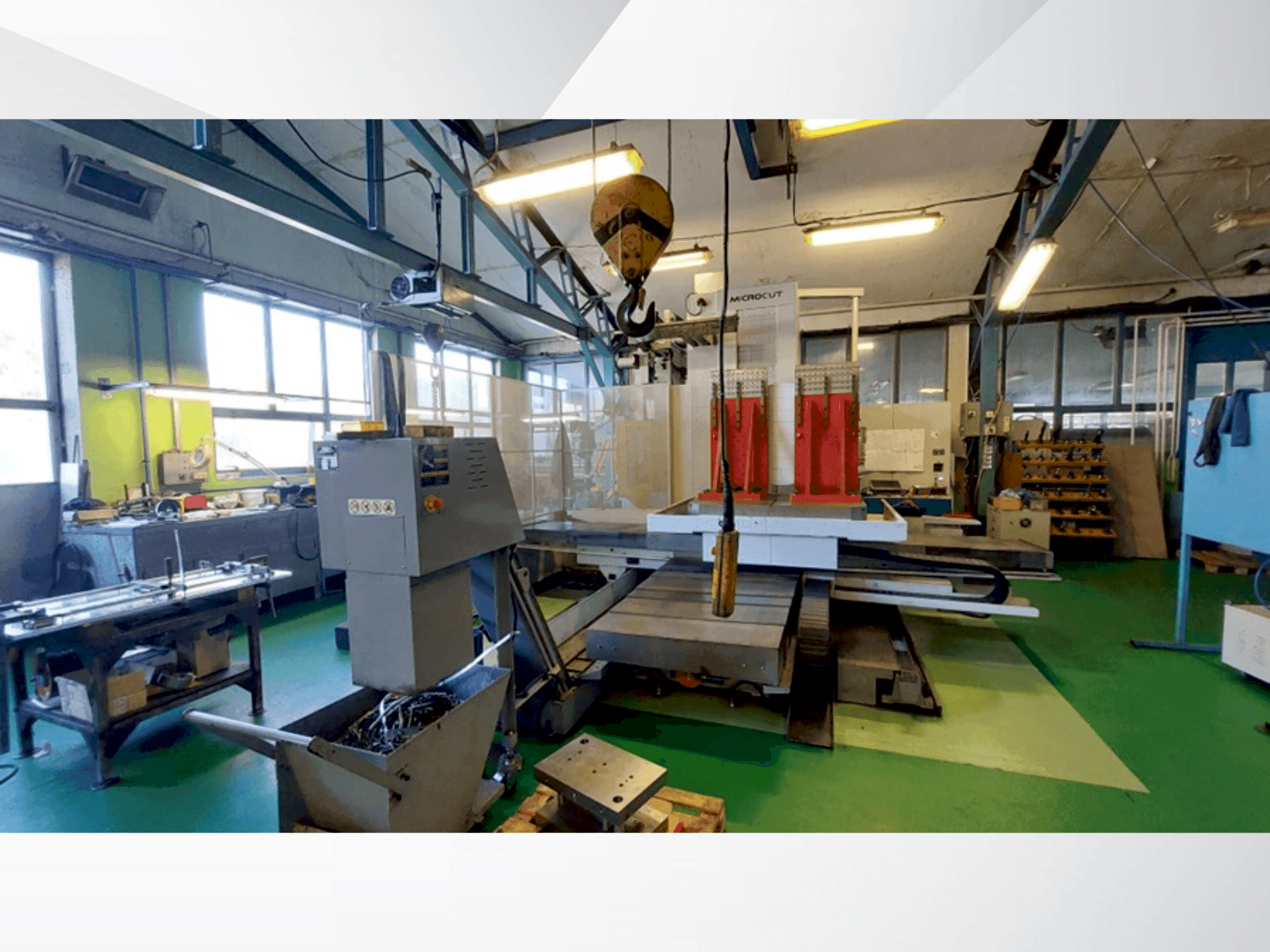

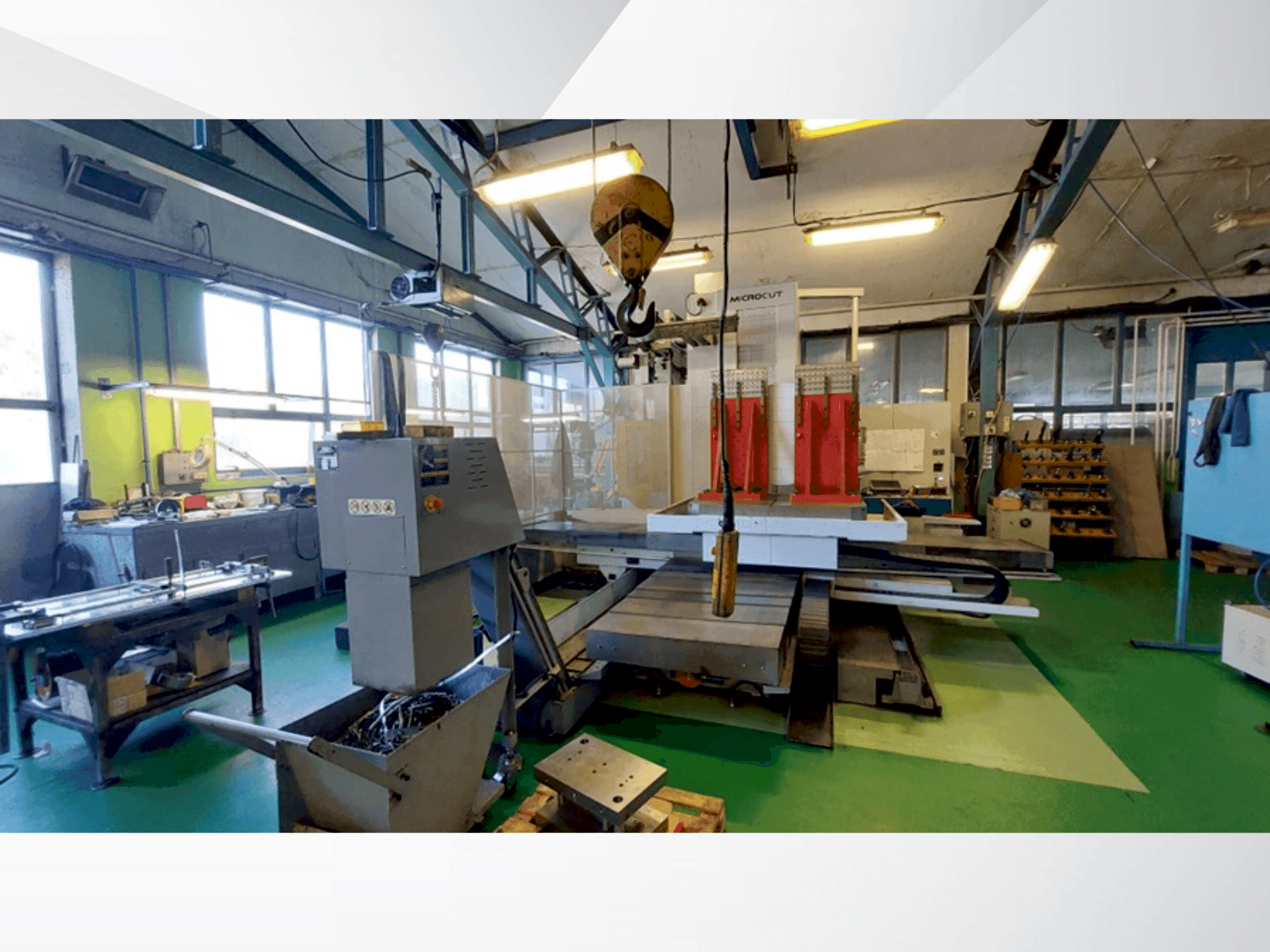

MICROCUT - HBM-4HU-MIL-MIC-2018-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used MICROCUT HBM-4 For Sale | gindumac.com

This 5-axis MICROCUT HBM-4 boring machine was manufactured in 2018. It features a robust Meehanite cast iron structure, high spindle speeds with low vibration, and a Fanuc 31iMB control for precision. The spindle supports a 150 mm diameter and operates at speeds up to 3000 rpm. The table can handle loads up to 5000 kg, with a working area of 1250 x 1500 mm. If you are looking to get high-quality boring capabilities, consider the MICROCUT HBM-4 machine we have for sale. Contact us for more information.

Overview

- brand: MICROCUT

- year: 2018

- MODEL: HBM-4

- production hours: 500

- application type: Other Machine Tools

- Location: Hungary

- machine type: Boring Machine (Metal)

- control unit brand: FANUC

Technical Information - MICROCUT HBM-4

Control Unit

- Control Brand: FANUC

- Control Model: 31iMB

Dimensions

- Machine Depth: 7750 mm

- Machine Height: 3700 mm

- Machine Weight: 22500 kg

- Table Length: 1250 mm

- Table Load: 5000 kg

- Table Width: 1500 mm

Movement

- B-axis Max: 0.001°

- X-axis Travel: 2200 mm

- Y-axis Travel: 1600 mm

- Z-axis Travel: 1600 mm

Technical Specification

- Spindle Power: 15 kW

- Spindle Speed: 3000 RPM

- Taper Size: ISO 50

Additional Information

Additional equipment

- Tool Changer Type: Arm type / Tool Positions: 60 / Max Tool Diameter: Ø125 mm / Max Tool Length: 300 mm / Max Tool Weight: 25 kg / Tool Change Time: 9 seconds

- Standard Accessories: Fanuc 0i CNC control, spindle oil cooler, chip conveyor, high-pressure cooling system (30 bar), hydraulic system and central lubrication, electronic handwheel, workspace lighting, spindle vibration monitoring

- Optional Features: 0.001° table indexing, 3D Fanuc option for universal milling head

Machine Benefits

Qualitative Machine Benefits

- High accuracy with fanuc 0i control

- Rigid design with robust table

- Meehanite cast iron structure for stability

- Dual cylindrical roller bearings on the spindle

- Absolute positioning system for axis movement

Technical Machine Benefits

- Torque: 740/863 nm / high-pressure cooling through the spindle

- Indexing: 1° (standard), 0. 001° (optional)

- X/y/z/w axis rapid: 12/12/12/6 m/min / x/y/z/w axis feed: 10/10/10/6 m/min

- The pictures show the clamps and tools belonging to the machine.

- Operating hours: ~700 hours.

- The machine has a continuous rotary table.

- Toolholder is sk50 din 69871

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing