Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

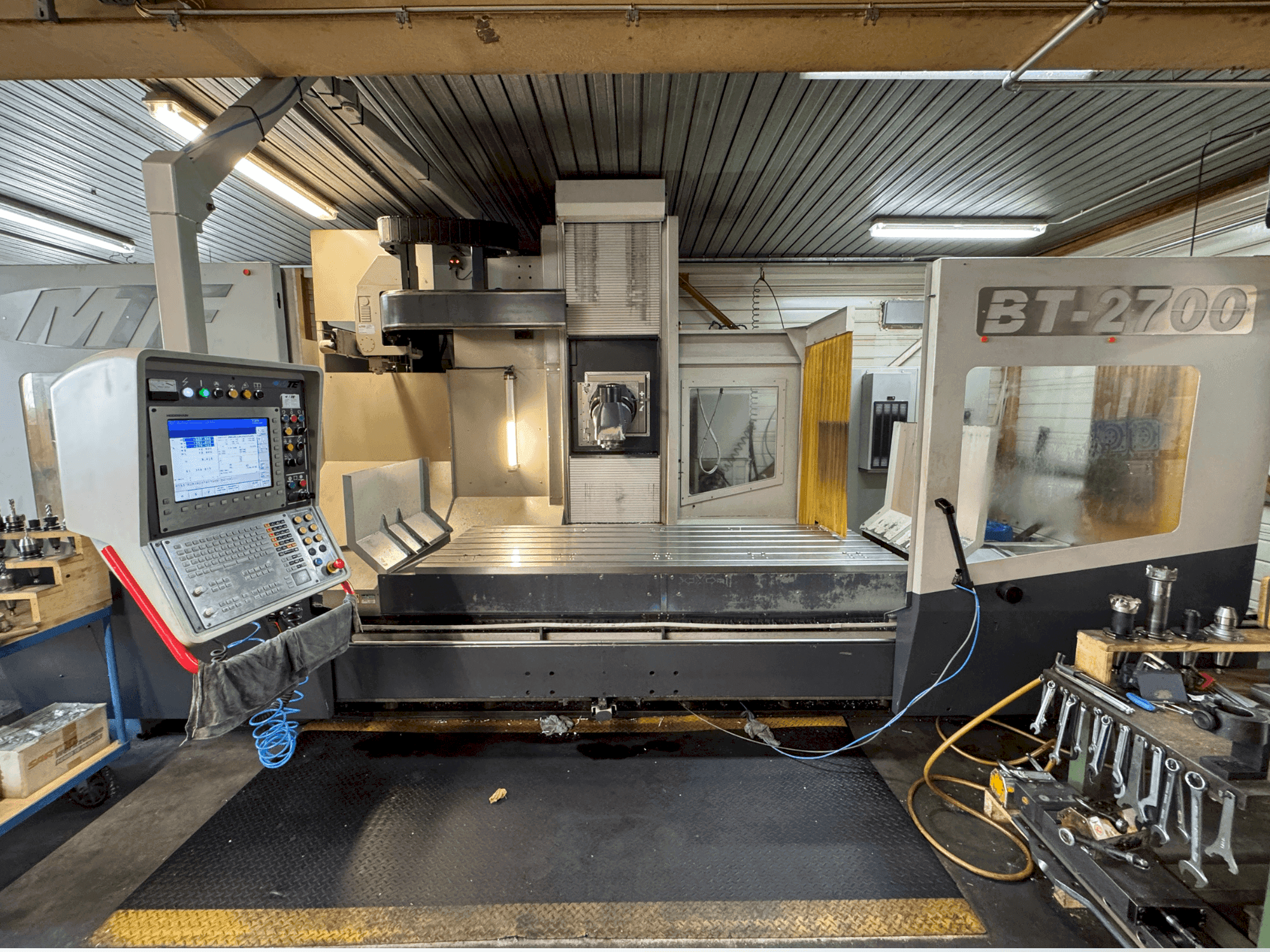

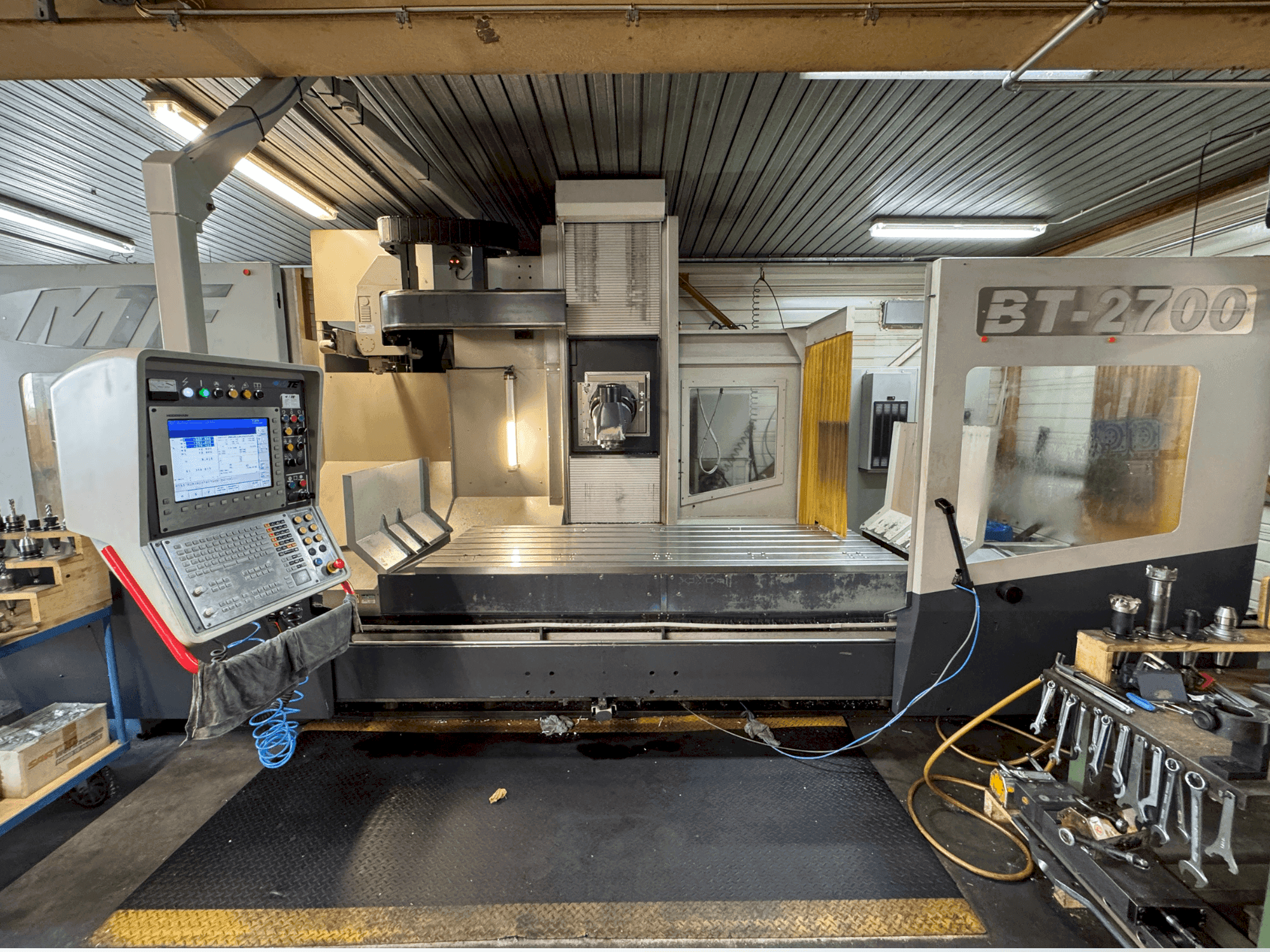

MTE - BT-2700DE-MIL-MTE-2015-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used MTE BT-2700 Milling Machine For Sale | gindumac.com

This 5-axis MTE BT-2700 CNC milling machine was manufactured in 2015. It features a robust Heidenhain ITNC 530 CNC control, a high-capacity clamping table of 2,700 mm length, and a maximum load of 9,000 kg. The machine offers a spindle speed up to 6,000 rpm and a rapid traverse rate of 25,000 mm/min. Ideal for high-precision, heavy-duty milling tasks. Contact us for more information about this machine.

Overview

- brand: MTE

- year: 2015

- MODEL: BT-2700

- production hours: 31491

- application type: Milling

- Location: Germany

- machine type: Bed Type Milling Machine

- control unit brand: HEIDENHAIN

Technical Information - MTE BT-2700

Control Unit

- Control Brand: HEIDENHAIN

- Control Model: iTNC 530

Dimensions

- Machine Weight: 2700 kg

Movement

- X-axis Travel: 2500 mm

- Y-axis Travel: 1200 mm

- Z-axis Travel: 1250 mm

Additional Information

Additional equipment

- Hydraulic system / Cooling unit with temperature control / Cooling lubricant system Control cabinet with lighting and air conditioning unit / Telescopic cover / Work area lighting / Safety fencing and secured access door

Machine Benefits

Technical Machine Benefits

- Clamping table/clamping surface length: 2700 mm / width: 1000 mm

- Maximum drive power: 32 kw from 198 rpm / maximum torque: 1120 nm (constant up to 376 rpm) / speed range: 0-6000 rpm / spindle speeds 6000 rpm: low range 0-984 rpm, medium range 918-2456 rpm, high range 2404-6000 rpm

- Cnc control with a 15. 1" flat screen and pivoting control pendulum

- On hours 32000

Extra Information

Capacity/Travel: X-axis (longitudinal travel): 2,500 mm Z-axis (vertical travel): 1,250 mm (optional) Y-axis (lateral travel): 1,200 mm (optional) Clamping table/Clamping surface: Length: 2,700 mm Width: 1,000 mm Maximum transport load: 9,000 kg Design: Diagonal (swivels in 2 planes) Speed range: 0-6,000 rpm Pitch/swivel positions: 2.5 x 1 (with Hirth gearing) 144 positions diagonal joint, 360 positions vertical joint Tool holder: DIN 69871 AD Pull stud: DIN 69872 Form A Taper: DIN 69871 Tool clamping force: 15,000 N Drive Main spindle: Motor / Make: Heidenhain main spindle drive Maximum drive power: 32 kW from 198 rpm Maximum torque: 1,120 Nm (constant up to 376 rpm) Speed control/gear: 3 speeds (oil-cooled) with automatic switching Spindle speeds 6,000 rpm: low range 0-984 rpm, medium range 918-2,456 rpm, high range 2,404-6,000 rpm Axis drive axis feeds: Axis drive motors: Heidenhain (digital drives) Maximum rapid traverse: (X/Y/Z axes) 25,000 mm/min Maximum working feed: (K/Y/Z axes) 15,000 mm/min Maximum average acceleration: 2 minutes* Maximum feed force: (X/Y/Z axis) 21,500 N Axis drive systems: X-axis (longitudinal) Ball screw (preloaded) ® 63x40mm Z-axis (vertical) Ball screw (preloaded) © 50x20mm Y-axis (transverse) Ball screw (preloaded) ® 50x20mm Clamping table/table surface: Number of T-slots: 7 Size of T-slots: mm22 H12 Reference slot: mm22 H 7 T-slot spacing: 140mm Space requirements: Length approx. Height approx. Width approx. BT 2700 (at = 1250mm) (at Y= 1200mm) Machine weight: Weight BT 2,700kg Connected load: approx. 7,200mm (without cross conveyor + 1,280 mm) approx. 3,250mm (without tool changer) approx. 4,900 mm approx. 18,500 mm KVA approx. 45 Basic machine equipment: HEIDENHAIN ITNC 530 (HSCI) CNC control with 15.1" flat screen and pivoting control pendulum for machine operation in front of and behind the machine. The machine bed, clamping table, machine column, and vertical saddle are made of GG30 lamellar graphite cast iron to improve damping properties. The milling slide is made of high-quality GJS-500 spheroidal graphite cast iron to ensure maximum rigidity and thus maximum mechanical precision of the slide axis. Automatic milling head made of cast steel (GS 60) with a diagonal design, tiltable, 2.5° / 2.5° (optional 2.5° x 1°) and a speed of 4,000 rpm (optional 3,000/6,000 rpm). Spindle orientation via the NC control Oil-cooled main spindle gearbox, 3 stages with automatic switching, a maximum power of 32 kW and a maximum torque of 1,520 Nm The gears in the gearbox are helical. The gears are made of chrome-nickel steel, hardened, and precision-ground. INA linear recirculating roller bearing guides in all 3 axes X-axis (lengths): 10 units, type: INA RUE 45 EL Z-axis (vertical): 4 bearings, type: INA RUE 55 EL Y-axis (transverse): 8 units, type: INA RUE 45 EL and additional flat guides as damping slides Hydraulic system: Rexroth Cooling unit with temperature control for cooling the gear oil. Main spindle drive and axis drives via Heidenhain AC motors (digital) Heidenhain linear measuring system (0.001 mm) in all axes Hydraulic counterbalance in the vertical axis Milling slides above and below the vertical axis are enclosed with a roller cover to protect the rear machine compartment Vertical axis (in the rear machine compartment) above and below the vertical saddle are enclosed with a bellows cover to protect the guideways, the ball screw, and the measuring system from contamination Automatic central lubrication of the axes and ball screws Cooling lubricant system for supplying cooling lubricant from the outside to the machining tools Control cabinet with lighting and air conditioning unit Telescopic cover to protect the guides and drive units in the X-axis Portable electronic handwheel, "Heidenhain HR-410" with axis selection Automatic temperature compensation Additional electric foot pedal for manual tool changes Splash guard on 4 sides with a large viewing window. The sliding doors on the front of the machine can be opened along the entire length of the clamping table. Additional sliding door at the rear of the work area. The sliding doors are equipped with safety switches in accordance with CE regulations and integrated into the machine's emergency stop circuit. Safety fencing Fell Protects the rear machine area with a secured access door Work area lighting Paint finish: graphite gray RAL 7024 / agate gray RAL 7038 Extension of the vertical travel of the machine from Z = 1000 mm to Z = 1250 mm Extension of the transverse travel of the machine from Y = 1000 mm to Y = 1200 mm Automatically swivelling milling head in diagonal design, with division 2.5°x 1° (Hirth tooth profile) Speed 6,000 rpm BIG Plus tool spindle: The tool spindle is equipped with a simultaneous taper and face contact for the tool Air cooling through the spindle: Compressed air can alternatively be supplied for tool cooling through the tool center (IKZ) in accordance with DIN 69871 Form AD Air cooling via coolant nozzles (external): Air supply to the tool/workpiece as an alternative to the coolant supply via external coolant nozzles on the tool spindle Minimum quantity lubrication Lubrix system: An oil-air mixture can alternatively be supplied through the tool center (IKZ) in accordance with DIN 69871 Form AD for tool cooling and lubrication. Automatic tool changer HN: Machine version with an automatic tool changer mounted on the machine stand. Max. tool diameter: Max. tool diameter with free auxiliary spaces in the magazine: 125 mm 250 mm Max. tool length: 380 mm Max. tool weight: 20 kg Chip conveyor: Chip conveyor mounted in the longitudinal direction of the machine between the machine stand and the clamping table, hinged belt design. Ejection on the right. Second chip conveyor: Chip conveyor mounted in the longitudinal direction of the machine in front of the machine table, hinged belt design. Ejection on the right. Cross conveyor: To reduce the overall length of the machine by 1300 mm by using a cross conveyor in hinged belt design on the left side with rear ejection. Simple splash guard: The machine is equipped with a simple splash guard instead of the standard safety and splash guard enclosure: Large sliding doors with viewing windows are mounted on the front and right rear of the machine table. HH TS 460 radio measuring probe system: Heidenhain TS632 radio measuring probe system enables reliable electronic measurement and alignment of workpieces in all positions of the milling head thanks to unrestricted signal transmission of radio waves using practical measuring cycles. - TS460 radio measuring probe system Bidirectional activation Steep cone DIN69871 SK40 M4 probe pin (ceramic shaft), length = 53 mm - Radio receiver Flexible antenna with TNC connector, connection cable (2 m) with connector for Heidenhain control i TNC 530 HSCI connection X 112

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing