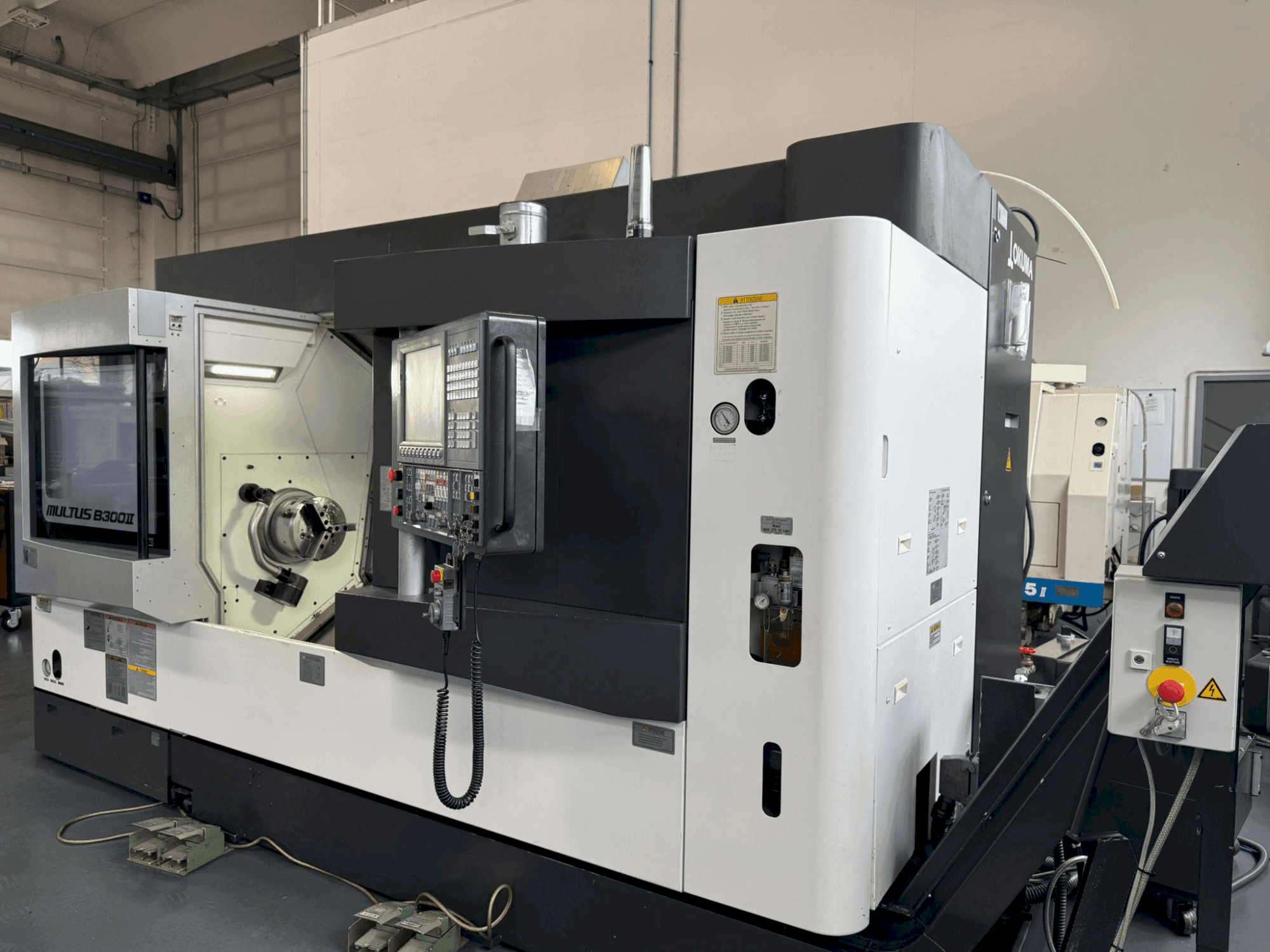

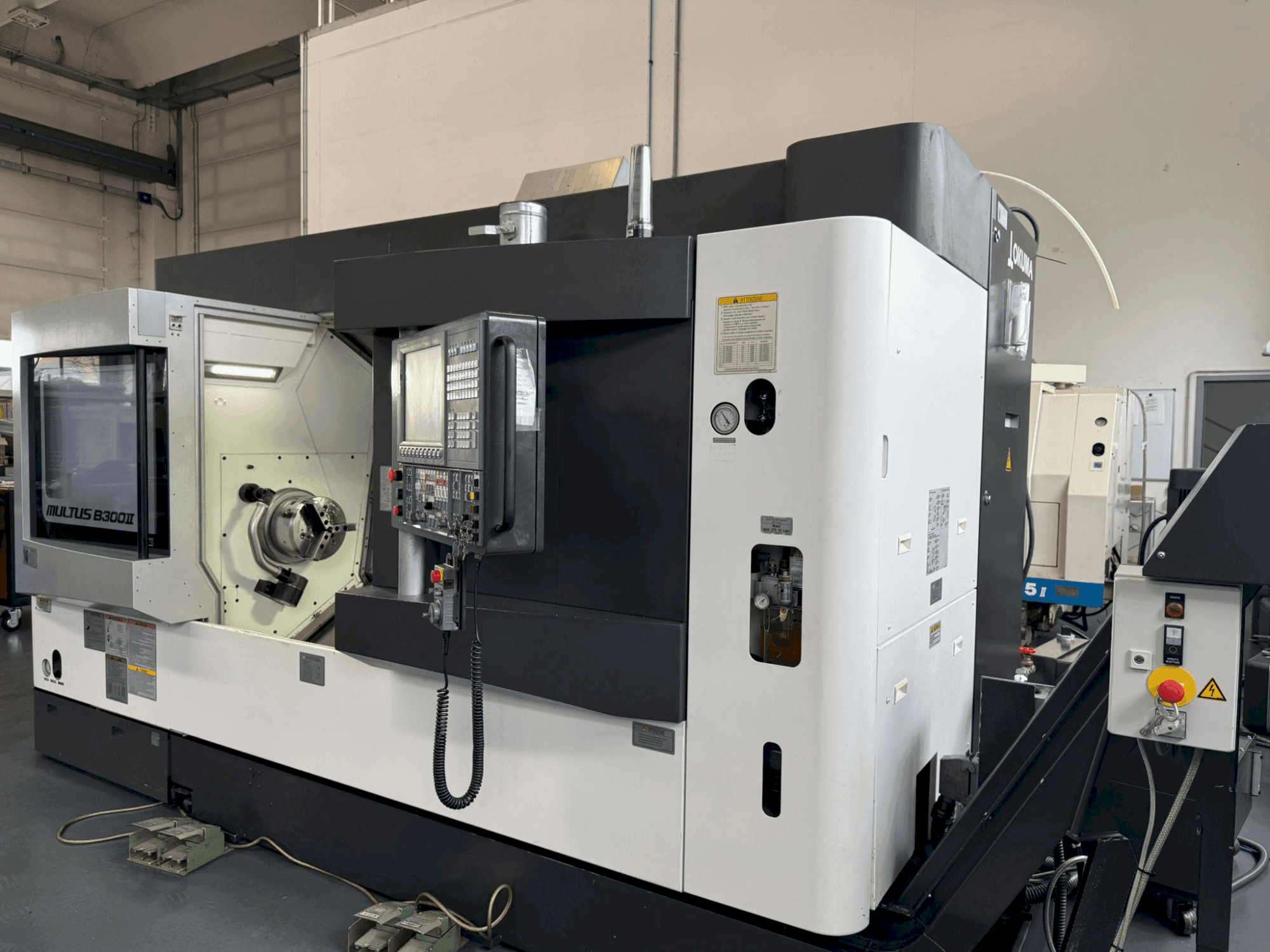

Okuma - MULTUS B300IIIT-TUR-OKU-2016-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used Okuma MULTUS B300II For Sale | gindumac.com

This 5-axis OKUMA MULTUS B300 II W was manufactured in 2016. It features an ASA 8 spindle offering 5,000 rpm and 65 mm bar capacity, capable of handling a max turning diameter of 630 mm. It includes a high-pressure coolant preparation of 70 bar, a continuous B-axis with HSK63, and a tool magazine with 60 positions, optimizing both turning and milling capabilities. If you are looking for high-quality turn-mill operations, consider this OKUMA machine. Contact us for more information about this machine.

Overview

- brand: Okuma

- year: 2016

- MODEL: MULTUS B300II

- application type: Turning

- Location: Italy

- machine type: Turn-Mill Centre

- control unit brand: OKUMA

Technical Information - Okuma MULTUS B300II

Control Unit

- Control Brand: OKUMA

- Control Model: OSP-P300S-H

Movement

- Y-axis Travel: 160 mm

Additional Information

Additional equipment

- 60 tool ATC / High-pressure coolant preparation: 70 bar/ External coolant pump: 0.8 kW, 6 bar, 20 L/min/ Electric spindle orientation /Air blast for chuck cleaning

- Collision Avoidance System (CAS)/Chip Conveyor Preparation/Big Bore Spindle ASA 6": 22/15 kW, 3800 rpm/ High-precision C-axis positioning/ Continuous B-axis/ Tool Magazine with 60 positions/ 0.1 Micron Resolution Software/ API Library 2 for OSP-P300S/ Standard Right Side Chip Conveyor/ 15 Bar Coolant Pump 20 L/min/ Filtration unit with 4 fabric filter bags (25 micron), pump 15 bar, 20 L/min

- SCHUNK ROTA THW+260-81R A8 chuck with KITAGAWA SS1770 cylinder for Big Bore main spindle

- SCHUNK ROTA THW+215-66 A6 chuck with KITAGAWA SS1452 cylinder for sub-spindle

- Y-Axis Machining Kit: Helical interpolation /Y-axis turning function with offset turning toolholders/ Coordinate conversion /Double pressure clamping system for main spindle chuck via M-codes (irreversible) /Double pressure clamping system for sub-spindle chuck via M-codes (irreversible)

- 5-Axis Machining Kit: Super NURBS on 5 axes /Vector control /DNC-DT interface /Tool position control/ 3D coordinate transformation /Helical interpolation (includes inclined plane profile software)

Machine Benefits

Technical Machine Benefits

- Main and sub spindle: asa 8, 15 kw, 5000 rpm, 651 mm bar capacity / max turning diameter: ⌀630 mm / swing and distance between spindle noses: 1290 mm / b-axis: continuous, indexing 0. 001°, hsk63, 11 kw, 6000 rpm / milling spindle hsk a63: 10000 rpm, 16/11 kw

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing