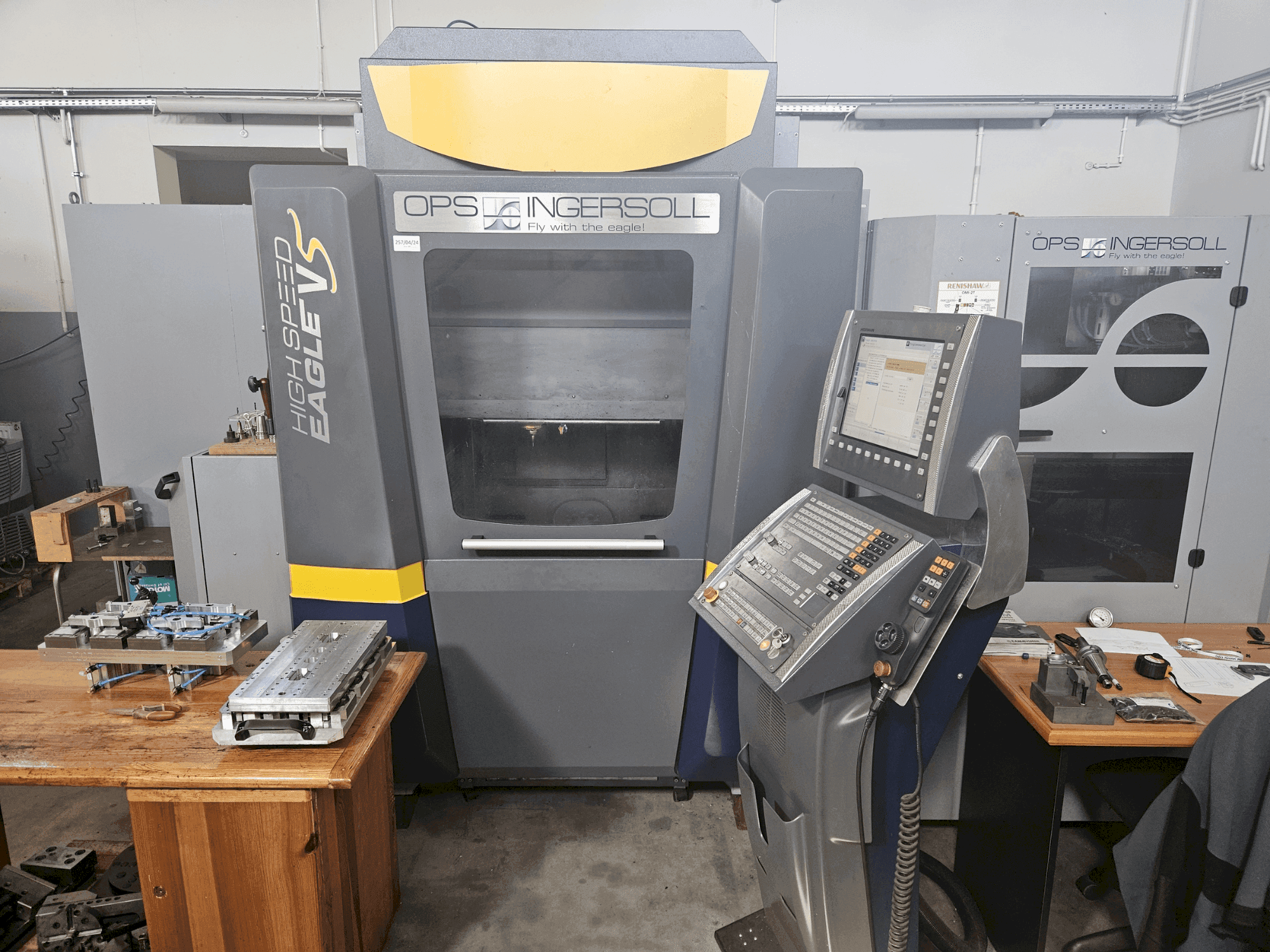

OPS INGERSOLL - HIGH SPEED Eagle V5PL-MIL-OPS-2017-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used OPS INGERSOLL HIGH SPEED Eagle V5 | Machining

This 5-axis OPS INGERSOLL Eagle V5 was manufactured in 2017, featuring a robust vertical machining center design. It boasts a high-speed Fisher HSK E40 spindle with speeds up to 42,000 rpm and a 32-tool magazine. The machine includes a 4/5-axis tilting rotary table, enhancing its versatility for complex machining tasks. Consider the opportunity to buy this OPS INGERSOLL Eagle V5 vertical machining center. Contact us for more information about this machine.

Overview

- brand: OPS INGERSOLL

- year: 2017

- MODEL: HIGH SPEED Eagle V5

- production hours: 8269

- application type: Milling

- Location: Poland

- machine type: Vertical Machining Centre

- control unit brand: HEIDENHAIN

Technical Information - OPS INGERSOLL HIGH SPEED Eagle V5

Control Unit

- Control Brand: HEIDENHAIN

- Control Model: iTNC 640 HSCI

Dimensions

- Machine Depth: 2800 mm

- Machine Height: 2450 mm

- Machine Weight: 7200 kg

- Table Load: 250 kg

Movement

- Number of Axes: 5

- X-axis Travel: 550 mm

- Y-axis Travel: 400 mm

- Z-axis Travel: 400 mm

Technical Specification

- Spindle Speed: 42000 RPM

Additional Information

Additional equipment

- 4/5-axis Tilting Rotary Table prepared for Pallet System

- B-axis Tilting Range: −120° to +60°

- C-axis Rotation: 360°

- B-axis Speed: 25 rpm

- C-axis Speed: 20 rpm

- Keller Dust Extraction System

- EROWA UPC Production Chuck Clamping System

- Tool Length and Diameter Laser Measurement, Broken Tool Detection

- Touch Probe (Renishaw)

- Precision Pack III – 5-axis Thermal Compensation

Machine Benefits

Technical Machine Benefits

- Spindle-to-table distance (min/max): 50–450 mm

- Table design: fixed dimensions: 650 × 500 mm

- T-slots: 5 × 14h12

- Torque (s1/s6 - 60%): 5. 9 nm / 6. 7 nm

- Tool magazine capacity: 32

- Max. Workpiece size: Ø400 × 380 mm

Extra Information

ECOTEC Energy-saving Function Table Adapter for 4th and 5th Axes HR410 Wireless Remote Control EROWA UPC Basic Chuck with EROWA ITS100 Adapter

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing