Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

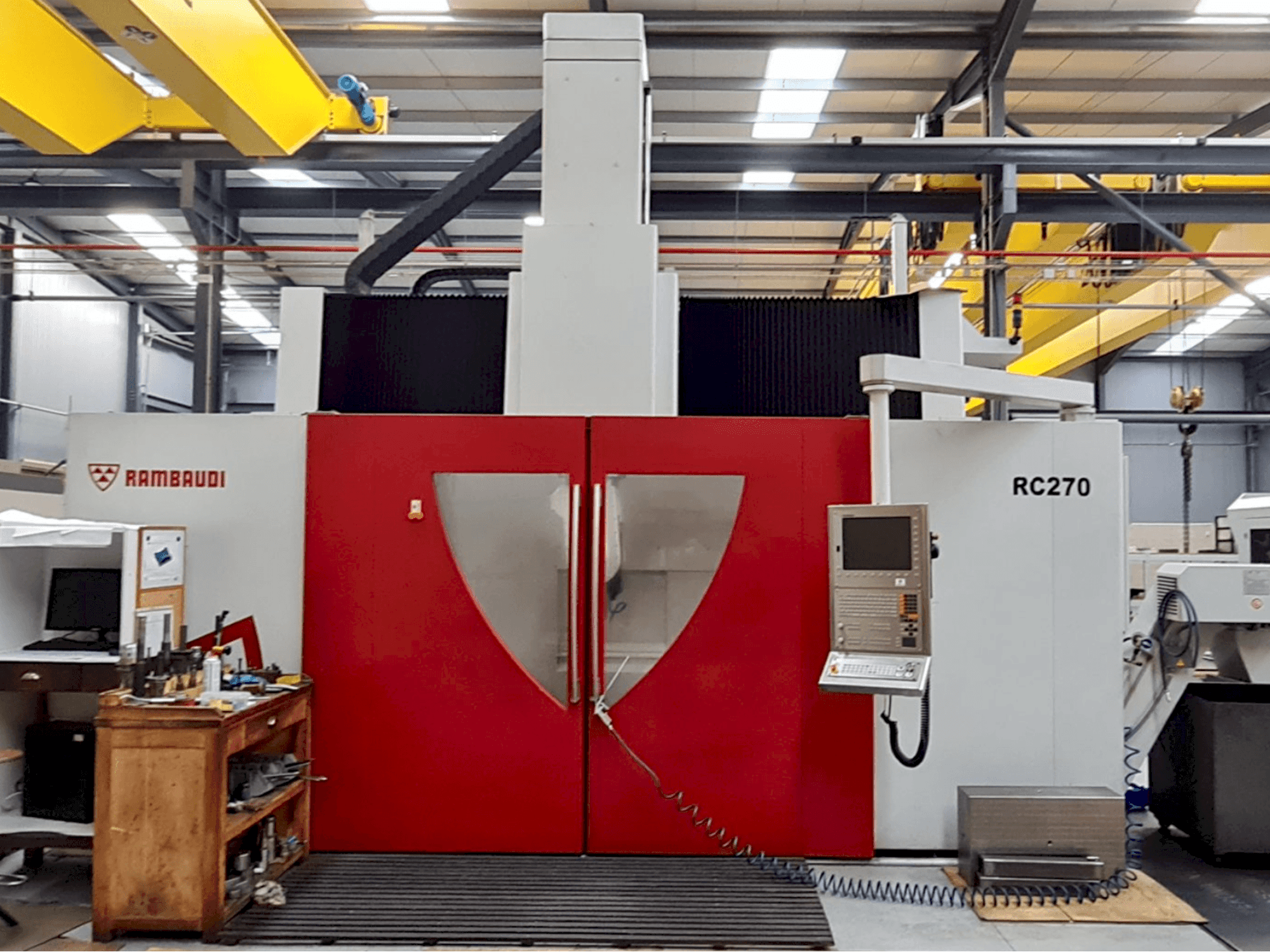

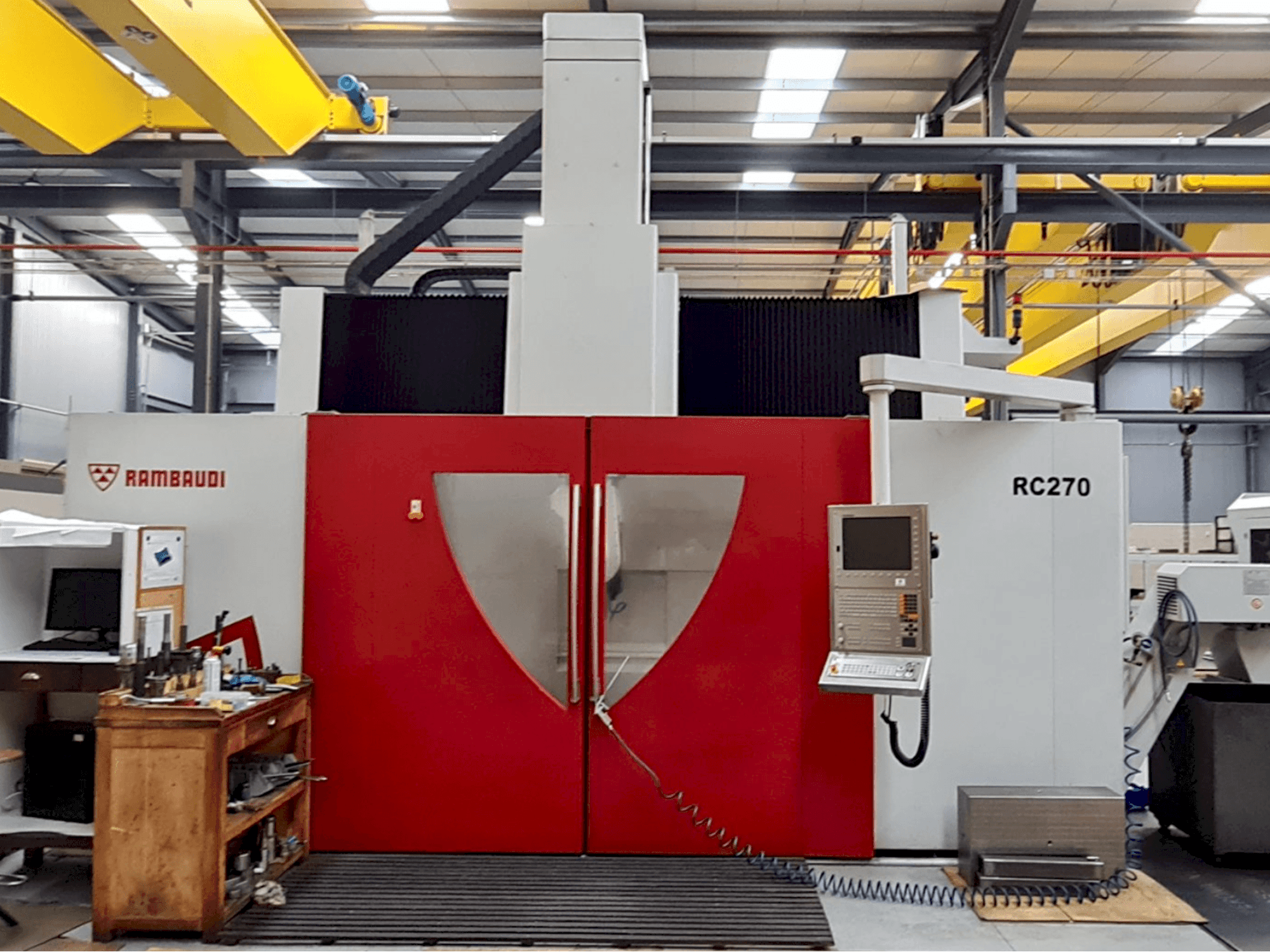

Rambaudi - RC 270PT-MIL-RAM-2014-00002

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- Rambaudi RC 270 Vertical Machining center

This Rambaudi RC 270 Vertical Machining center was manufactured in the year 2014. It is equipped with a HEIDENHAIN iTNC 530 HSCI control unit and has 5 axis. The spindle speed is at 24000 rpm and runs with a HSK-A63 tool taper. The machine has operated 38428 power on hours and 23655 cutting hours. It stands out for its movable crossbeam which makes the machining centre suitable for high-speed machining with 5 axes. See photo and video gallery for more impressions. Extract of original tech specs (EN) attached as PDF below.

Overview

- brand: Rambaudi

- year: 2014

- MODEL: RC 270

- production hours: 23655

- application type: Milling

- Location: Portugal

- machine type: Vertical Machining Centre

- control unit brand: HEIDENHAIN

Technical Information - Rambaudi RC 270

Control Unit

- Control Brand: HEIDENHAIN

- Control Model: iTNC530 HSCI

Movement

- Number of Axes: 5

- X-axis Travel: 2700 mm

- Y-axis Travel: 2200 mm

- Z-axis Travel: 1250 mm

Technical Specification

- Spindle Speed: 24000 RPM

Additional Information

Machine Benefits

Qualitative Machine Benefits

- Numeric control milling centre with movable crossbeam, suitable for high-speed machining with 5 axes

- Two lateral columns on which crossbeam runs

- A crossbeam that supports the ram holder cross saddle and slide on the columns

- A ram that slides vertically inside the cross saddle

- A head fixed to the lower part of the ram

- A working table in the center of the columns, with the following characteristics: 2500 x 2000 mm // 10000 kg/m2 // 300 mm thickness of cast iron table // 8 t-slots - width 28mm

- The machine is equipped with a 2-axis glob 89 g milling head (c and a continous)

- Inside of the head forks is housed the spindle with 24000 rpm, hsk-a 63 tool taper

Technical Machine Benefits

- X and x1 = 2200 mm // speed: 40 m/1' // longitudinal translation of the crossbeam on 2 columns

- Y = 2700 mm // speed: 40 m/1' // transversal translation of the ram holder cross saddle on the crossbeam

- Z = 1250 mm // speed: 40 m/1' // vertical translation of th eram on the cross saddle

- C continous = 400 (+/- 200 °) // rotation of the head around the ram vertical axis

- A continous = 230 ° (+ 120 °, -110 °) // rotation of the electrospindle support inside the head fork

- Precision of linear machine axes (x, x1, y, z): p = 0. 015 mm / transducer optical line

- Precision of polar machine axes (c,a): 15 arc sec - repeatability 10 arc sec / transducer encoder

- Torque: c, a continous = 1000 nm // c, a braked = 4000 nm

Extra Information

38428 machine on hours // 23655 cutting hours

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing