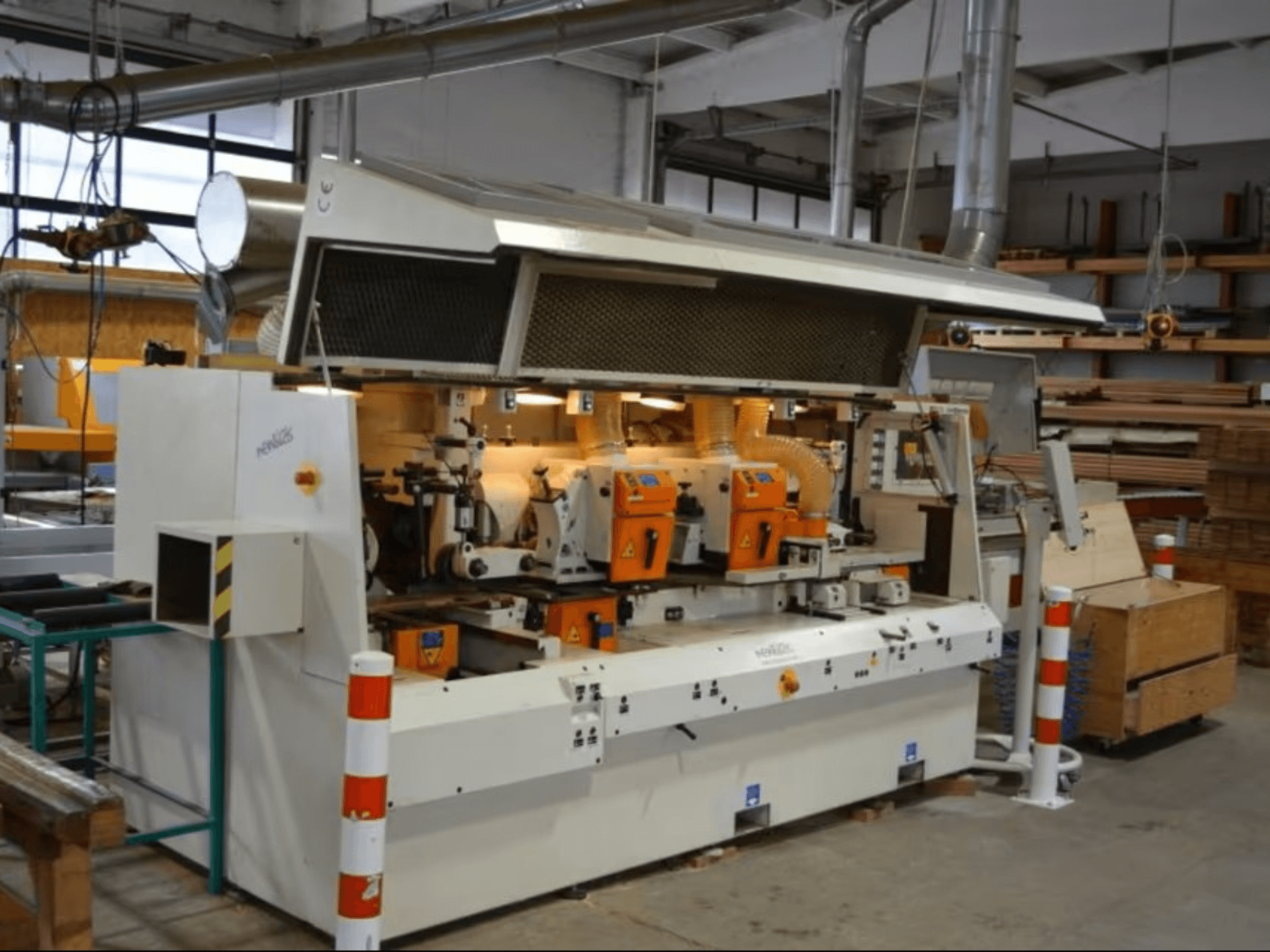

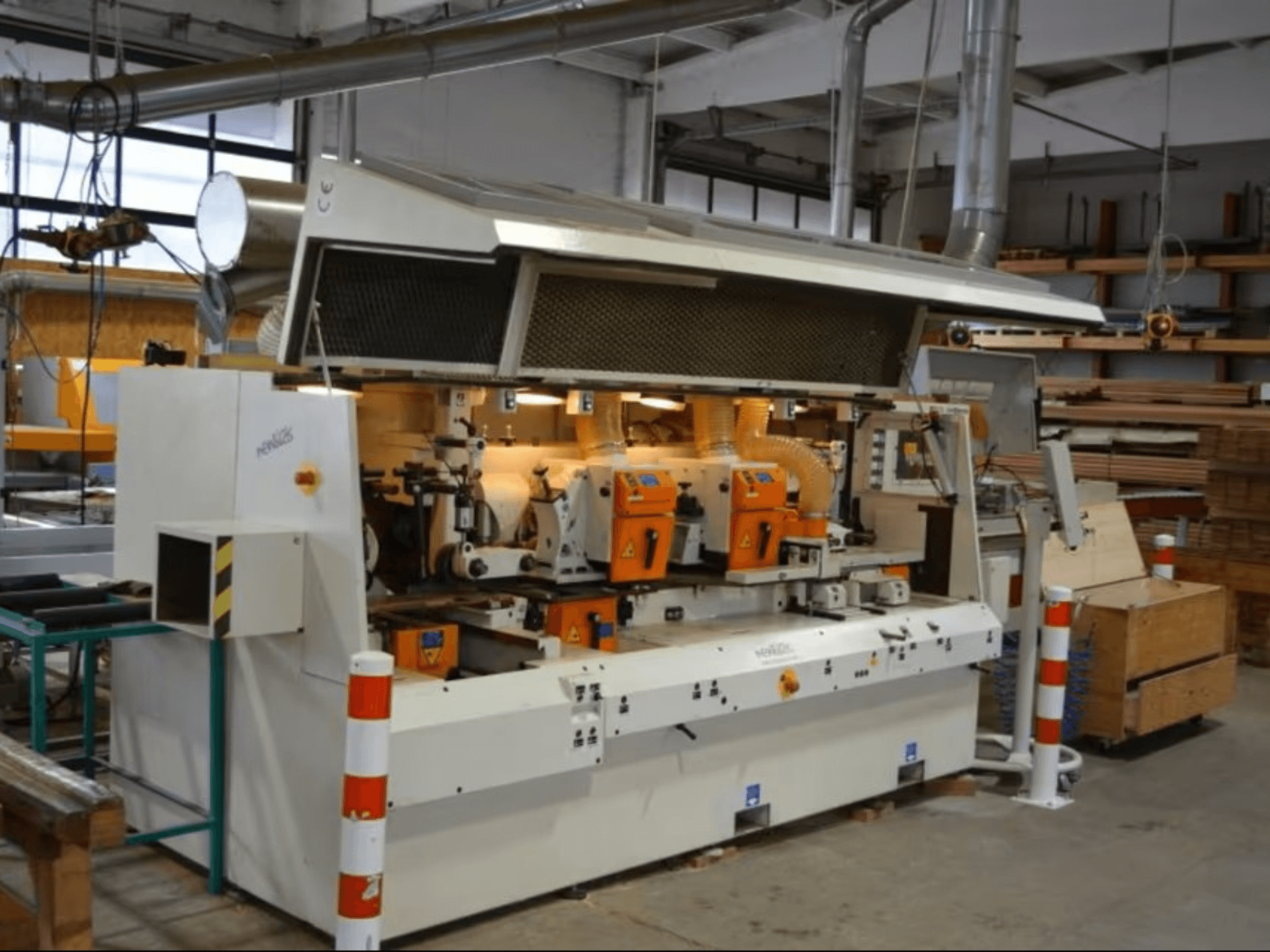

SCM - Superset NTEDE-MIL-SCM-2008-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Wood Working

- ➤ Used SCM Superset NTE Wood Mill For Sale | gindumac.com

This SCM Superset NTE was manufactured in 2008. A robust used profile milling machine featuring a touchscreen operation, 6 spindles including a UNIWELLE, and a spindle speed of 8300 rpm. It offers a working width up to 240 mm and includes a quick-change spindle system with Powerlock HSK 85. Ideal for detailed woodworking with its comprehensive tooling and motor-driven feed rollers. Contact us for more information about this machine.

Overview

- brand: SCM

- year: 2008

- MODEL: Superset NTE

- application type: Milling (Wood)

- Location: Germany

- machine type: Wood Mill

Technical Information - SCM Superset NTE

Dimensions

- Table Length: 2500 mm

Technical Specification

- Spindle Speed: 8300 RPM

Additional Information

Configuration: 6 spindles + 1 universal spindle (UNIWELLE) = 7 shafts; suitable for profiling/cutting

Control: MOBILE 10 touchscreen

Interface/Tooling system: HSK 85S Powerlock; T-SET spindle quick-change; quick-clamping devices

Working range:

Working width (finished): 15–240 mm

Working height (finished): up to 125 mm

Minimum workpiece length: 450 mm

Spindles:

Speed: 6,000 / 8,300 rpm

Diameter: 40 mm

Mounting length: vertical 220 mm, horizontal 250 mm

Axial adjustment: vertical 75 mm, horizontal 45 mm

Flight circle diameter: dressers 120–140 mm; profile spindles 100–200 mm

Profiling depth of 2nd lower shaft with Ø200 mm tool: 15 mm

Motors:

Feed motor: 4 kW (inverter-controlled)

Dressing/planing spindle: 7.5 kW

Right vertical spindle: 7.5 kW (Powerlock HSK 85)

Left vertical spindle: 7.5 kW (Powerlock HSK 85)

Upper horizontal spindle 1: 7.5 kW (quick clamping)

Upper horizontal spindle 2: 7.5 kW (Powerlock HSK 85)

Lower horizontal spindle: 7.5 kW (Powerlock HSK 85)

Universal spindle: 7.5 kW (quick clamping)

Feed system:

Feed speed: 6–36 m/min (via inverter)

Feed rollers: Ø140 mm; 2 rollers 140 x 25 per feed shaft

Motor-driven feed roller in work table and outfeed table

Two feed units after upper spindles to reduce center distance from 620 to 450 mm

Tables and guides:

Feed table length: 2,500 mm

Adjustment range for feed table and infeed guide: 10 mm

Pressures, guides, and safety:

Horizontal pressure before the planer with on/off switch

Horizontal pressure device before the planing shaft, switchable from control panel

Pneumatic pressure shoes in front of upper horizontal spindles

Pressure shoes at the front of the horizontal spindle guard

Hardened insert in work table before the planer

Lighting inside protective cover

Lubrication:

Forced lubrication (basic equipment)

Manual central lubrication

Manual pump for work table lubrication

Positioning/adjustment:

Electronic horizontal positioning

Electronic tool diameter setup/adjustment

Extraction:

Required extraction capacity: min. 10,443 m³/h

Other:

On/off switch for feed unit before the planer

Additional equipment

Extraction hose included

Powerlock mounting bracket included

Tooling included for HSK spindles; 240 mm cutterheads installed on horizontal spindles

Note: Not all tools shown are included

Documentation: spare parts catalog (8 complete PDF catalogs)

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing