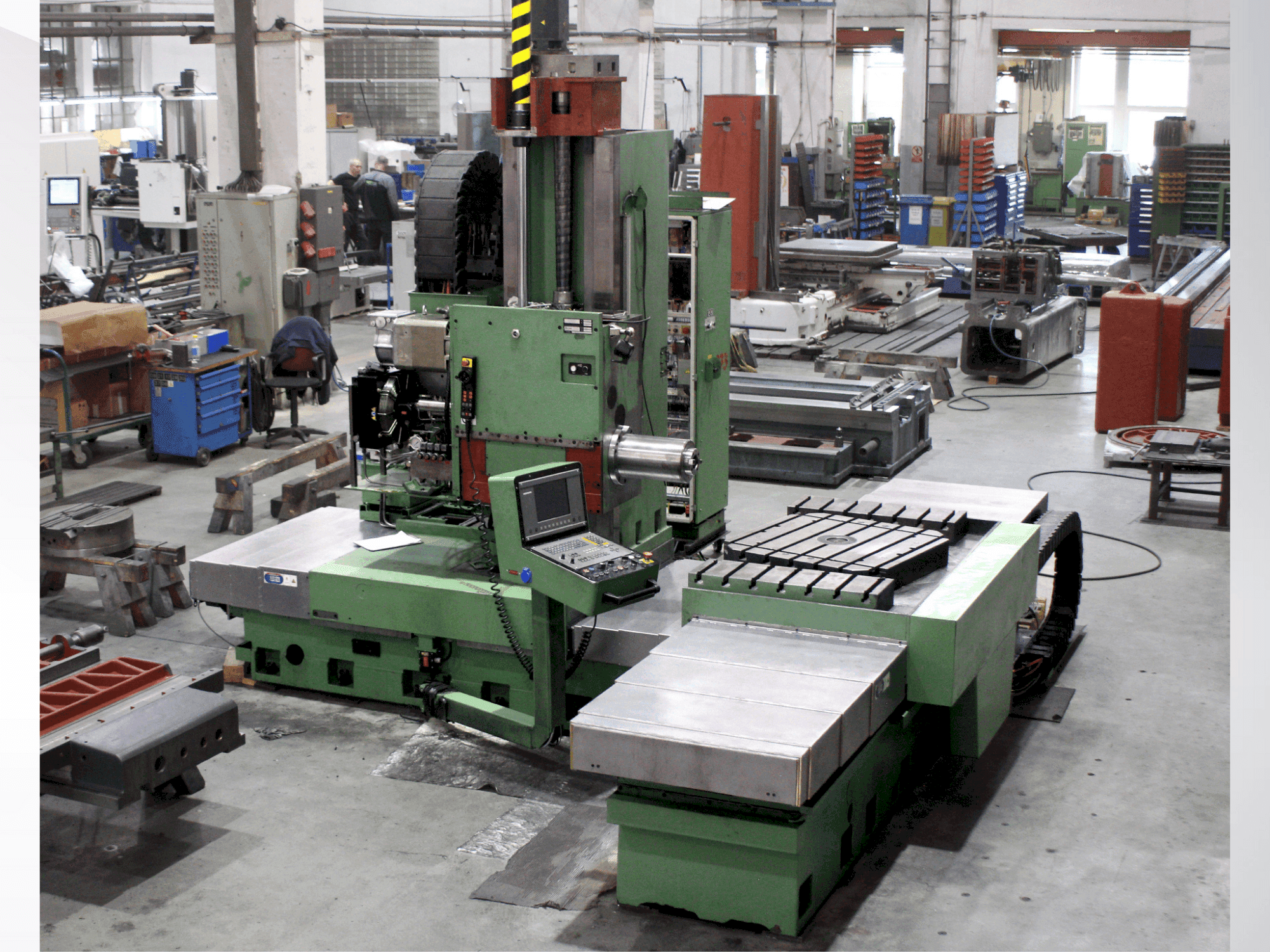

TOS - WFQ 80 CNCCZ-BOR-TOS-2008-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used TOS WFQ 80 CNC Boring Mill For sale | gindumac.com

This 4-axis TOS WFQ 80 CNC boring machine was manufactured in 2008. It features a working spindle diameter of 128 mm, a clamping taper of 50 ISO, and a spindle speed of 3500 rpm. The table can handle loads up to 5000 kg with additional supports and includes a chip conveyor and SIEMENS motors and drives. A great opportunity to buy this TOS WFQ 80 CNC boring machine. Contact us for further details regarding this boring machine.

Overview

- brand: TOS

- year: 2008

- MODEL: WFQ 80 CNC

- application type: Other Machine Tools

- Location: Czech Republic

- machine type: Boring Machine (Metal)

- control unit brand: HEIDENHAIN

Technical Information - TOS WFQ 80 CNC

Control Unit

- Control Brand: HEIDENHAIN

- Control Model: TNC426

Dimensions

- Table Length: 850 mm

- Table Load: 3000 kg

- Table Width: 850 mm

Movement

- X-axis Travel: 1600 mm

- Y-axis Travel: 920 mm

- Z-axis Travel: 950 mm

Technical Specification

- Spindle Speed: 3500 RPM

Additional Information

Machine Benefits

Qualitative Machine Benefits

- Precision control, very good condition

Technical Machine Benefits

- Diameter of the working spindle: 128 mm

- Retrofitted in 2008

- Robust table design

Extra Information

Machine still under power // Machine was checked and refurbished in 2024: ■ cleaning, technical inspection of the machine ■ replacement of the Heidenhain TNC426 control system ■ complete inspection of the electrical cabinet ■ replacement of damaged cables ■ repair of the control panel ■ repair of the complete geometry of the machine (geometric accuracy protocol on request) ■ inspection of the drives (new bearings for the X+Z ball screw bearings) ■ inspection of the headstock ■ inspection of the hydraulic unit ■ inspection of lubrication and reinforcement ■ new telescopic covers

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing