Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

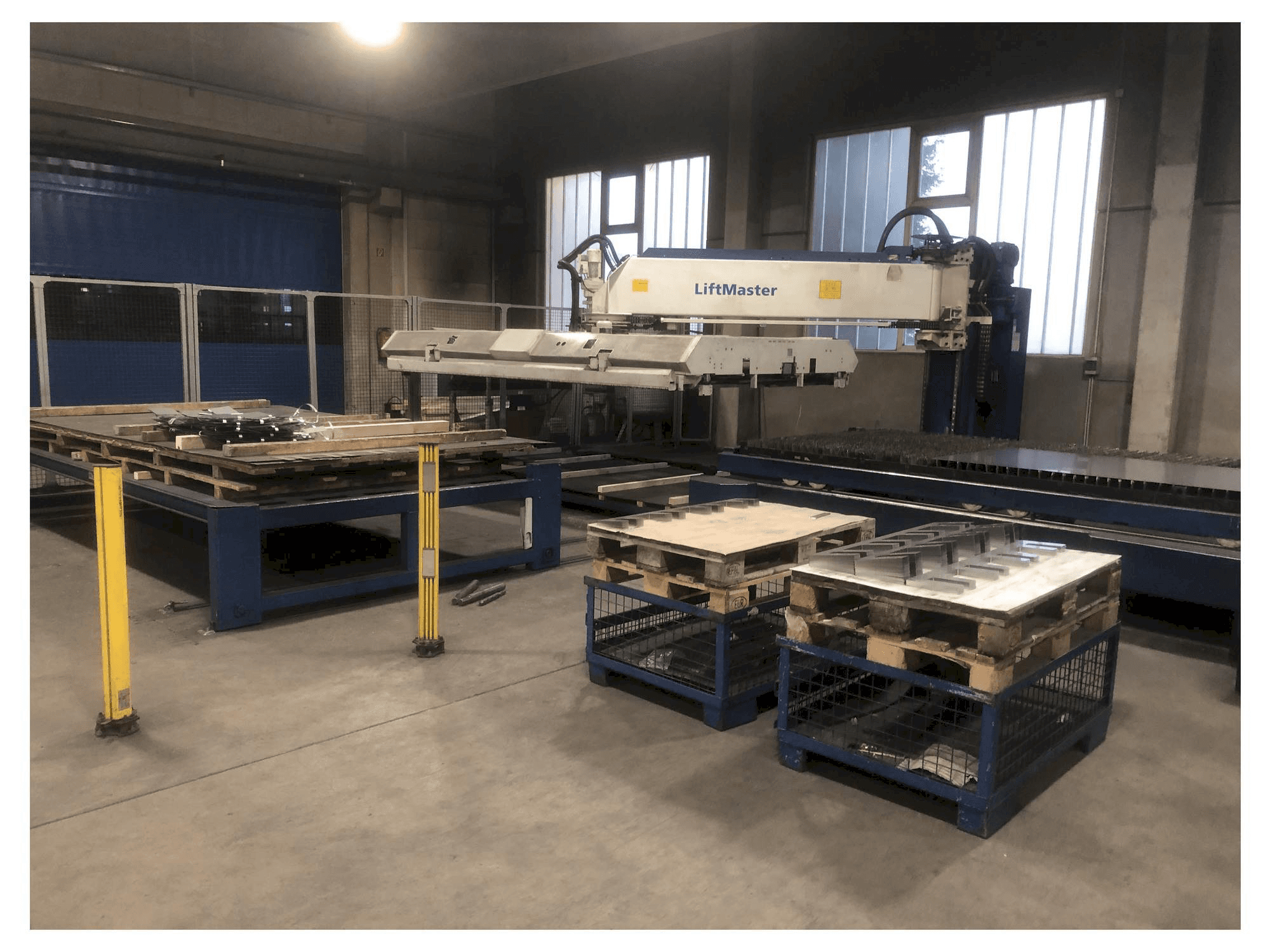

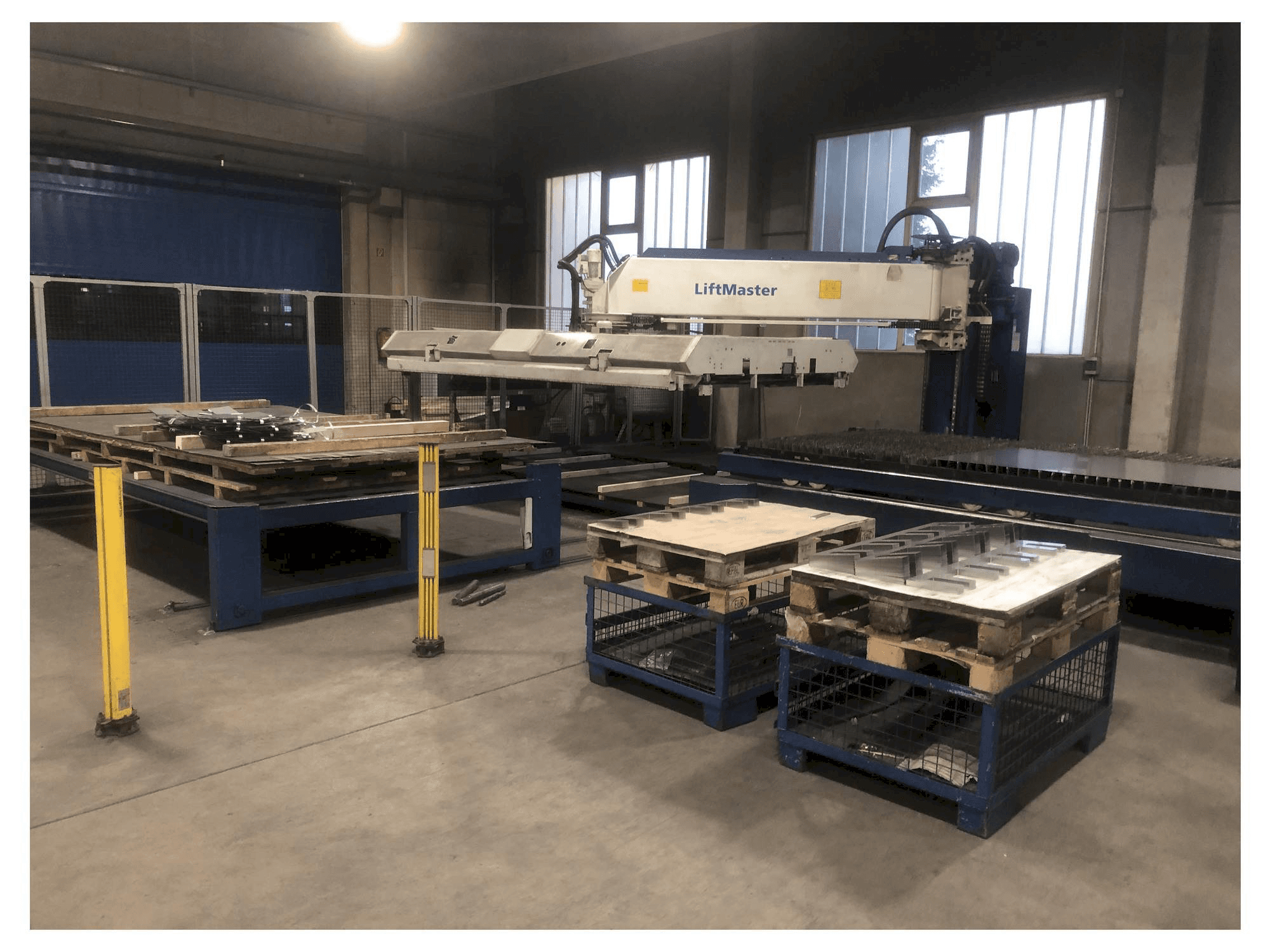

TRUMPF - TruLaser 5040 + LiftmasterDE-LAS-TRU-2007-00003

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Sheet Metal Machinery

- TRUMPF TruLaser 5040 + Liftmaster Laser Cutting machine

This TRUMPF TruLaser 5040 + Liftmaster Laser Cutting machine was made in 2007. It is equipped with a SIEMENS SINUMERIK 840D control unit. The machine has a laser power of 5,0 kW.

Overview

- brand: TRUMPF

- year: 2007

- MODEL: TruLaser 5040 + Liftmaster

- application type: Cutting

- Location: Germany

- machine type: CO2 Laser Cutting Machine

- control unit brand: SIEMENS

Technical Information - TRUMPF TruLaser 5040 + Liftmaster

Control Unit

- Control Brand: SIEMENS

- Control Model: Sinumerik 840D

Technical Specification

- Laser Power: 5 kW

Additional Information

Machine Benefits

Qualitative Machine Benefits

- Cutting gas pressure setting programmable

- Controlline capacitive height control and process control

- Laser cutting head with 7. 5" lens and laser cutting head with 10" lens for truflow 6000

- Laser cutting head with 5" lens and laser cutting head with 7. 5" lens for truflow 5oo0

- Cutting head quick-change device

- Drives: gantry drive in combination with linear drives direct drives

- Automatic pallet changer

- Closed machine frame with integrated laser unit - laser unit: truflow 5000 high-frequency excited co2 laser, maintenance-free turbo radial fan, cooling unit, logbook function

- Fully encapsulated and ventilated with nitrogen,

- Longitudinal conveyor belt for small parts/waste

Technical Machine Benefits

- Software licence is included

- Fast processing with sprintline in all sheet thicknesses, programmable power cycles

- Contourline for the production of small holes

- Pierceline

- Spraying device for safe thick sheet processing

- Automatic sheet metal outer edge detection

- Safety: multi-beam light barriers, beam guidance

- Nitroline high-pressure cutting

- Automatic focus position adjustment focusline - laser power control

- Position laser diode

Extra Information

Working area: 4OO0 x 2000 x 1 15 mm Sta nd equipment: - PlasmaLine - Microweld - Automatic nozzle cleaning - Automatic switch-off - Work area lighting - Sinumerik 840D control system: Open control system on PC basis, simple operation, online help, integrated e-shop, diagnostic functions, maintenance logbook, technology data, teleservice - Workshop programming monitoring system, multi-chamber extraction system and compact dust extractor, safety cabin - Installation, commissioning and instruction - RJ45 network connection via teleservice installation - 3.5" floppy disk drive - TFT color screen Ouer conveyor belt left with container LiftMaster Peeling device and sheet thickness gauge Pallet handling extension (P) + 1x double trolley machine have a maintenance contract with Trumpf quartz tube replacement was carried out in 2022/2023. 00% power of 5KW.

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing