Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

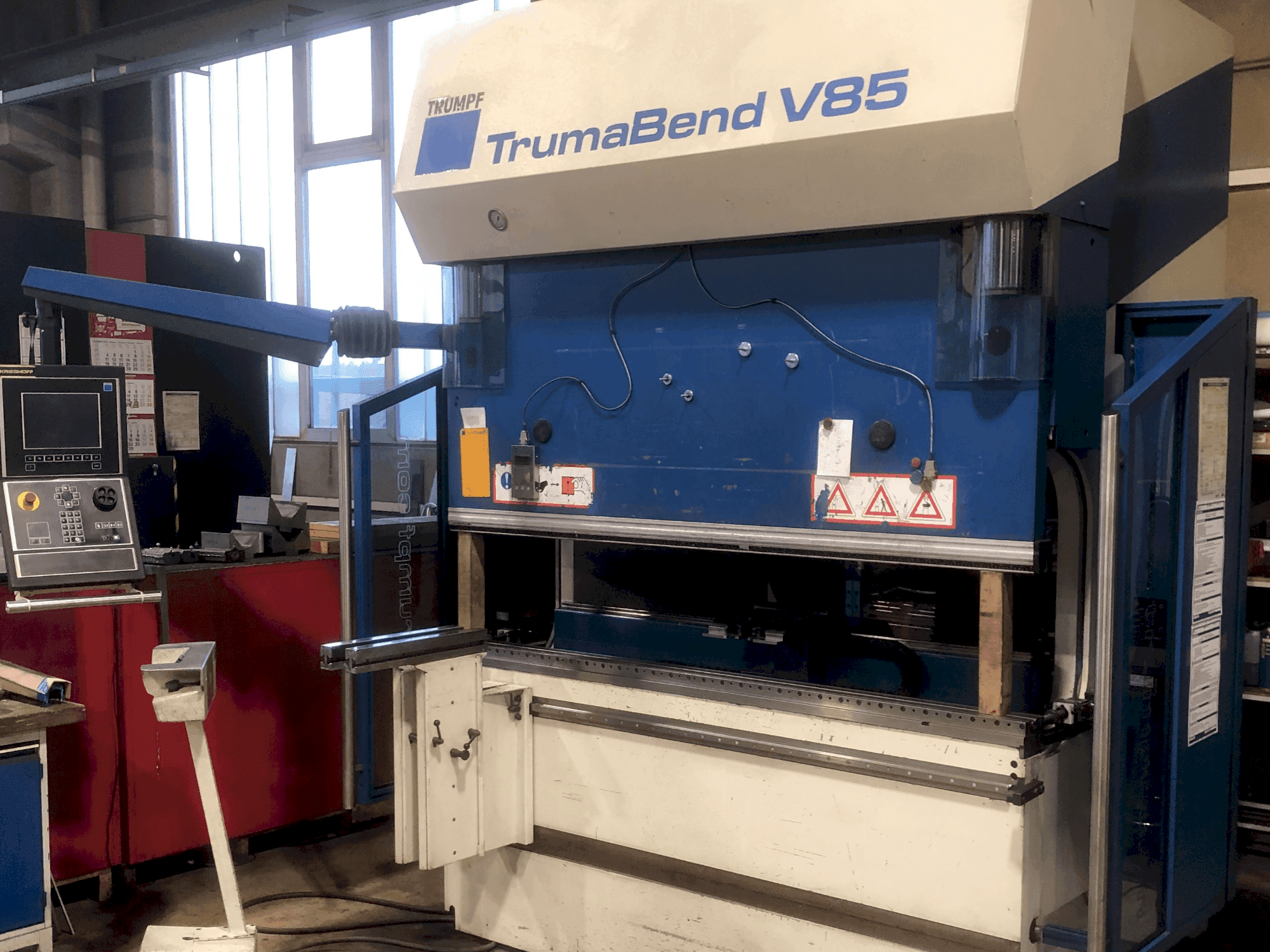

TRUMPF - TrumaBend V85XDE-BEN-TRU-2003-00005

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Sheet Metal Machinery

- TRUMPF TrumaBend V85X Bending machine

This TRUMPF TrumaBend V85X Bending machine was manufactured in 2003 in Germany. It has a press force of 850 kN and a bending length of 2050 mm. Free upright clearance is 1750 mm. The standard equipment covers a sturdy machine frame, pressure beam with high bending strength and CNC backgauge with rack and pinion drive for X- and R-axis. As special features the machine has an increased installation height and stroke by 150 mm each to 535 mm, a 5-axes backgauge system, a hydraulic and hardened upper tool clamping, a hydraulic lower tool clamping, CNC crowning, a BendGuard safety device, a support front console and control cabinet climatization (for 2-, 4-axis backgauge systems). It comes with a bending tool package. License for software, ToPs 600 for bending, included. See attached original tech specs positions as PDF (German).

Overview

- brand: TRUMPF

- year: 2003

- MODEL: TrumaBend V85X

- production hours: 34599

- application type: Bending

- Location: Germany

- machine type: Press Brake

- control unit brand: TRUMPF

Technical Information - TRUMPF TrumaBend V85X

Control Unit

- Control Brand: TRUMPF

- Control Model: 2D graphic control

Movement

- Number of Axes: 5

Technical Specification

- Bending Length: 2050 mm

- Pressing Force: 850 Kn

Additional Information

Additional equipment

- Tool Package

- Software ToPs 600 for bending: License included

Machine Benefits

Qualitative Machine Benefits

- Installation height and stroke increased by 150 mm each to 535 mm

- Back gauge system 5 axes

- Hydraulic and hardened upper tool clamping

- Hydraulic lower tool clamping

- Cnc crowning

- Bendguard safety device

- Support console

- Front control cabinet

- Climatization (for 2-, 4-axis backgauge systems)

- Preparation for acb®

Technical Machine Benefits

- Free upright clearance 1750 mm

- Installation height 385 mm

- Electrical equipment for three-phase current 400 v / 50 hz

- Modern block hydraulics

- Cnc backgauge with rack and pinion drive, for x- and r-axis, danger-free movement of the stop fingers from the front

- "modufix" upper tool holder system, manual

- Bottom tool holder for ev dies, manual clamping, displacement programmable

- Safety device

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing