Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

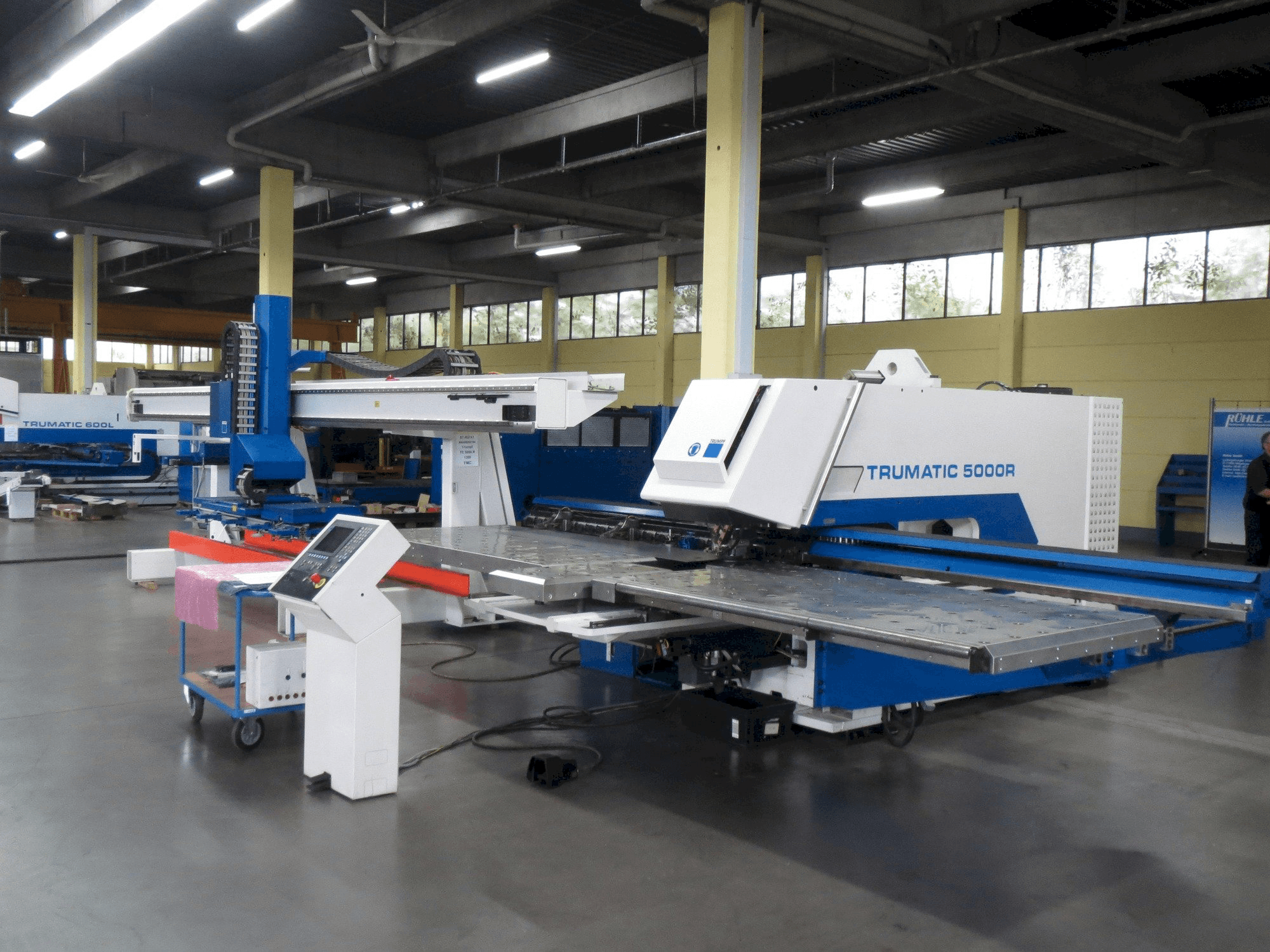

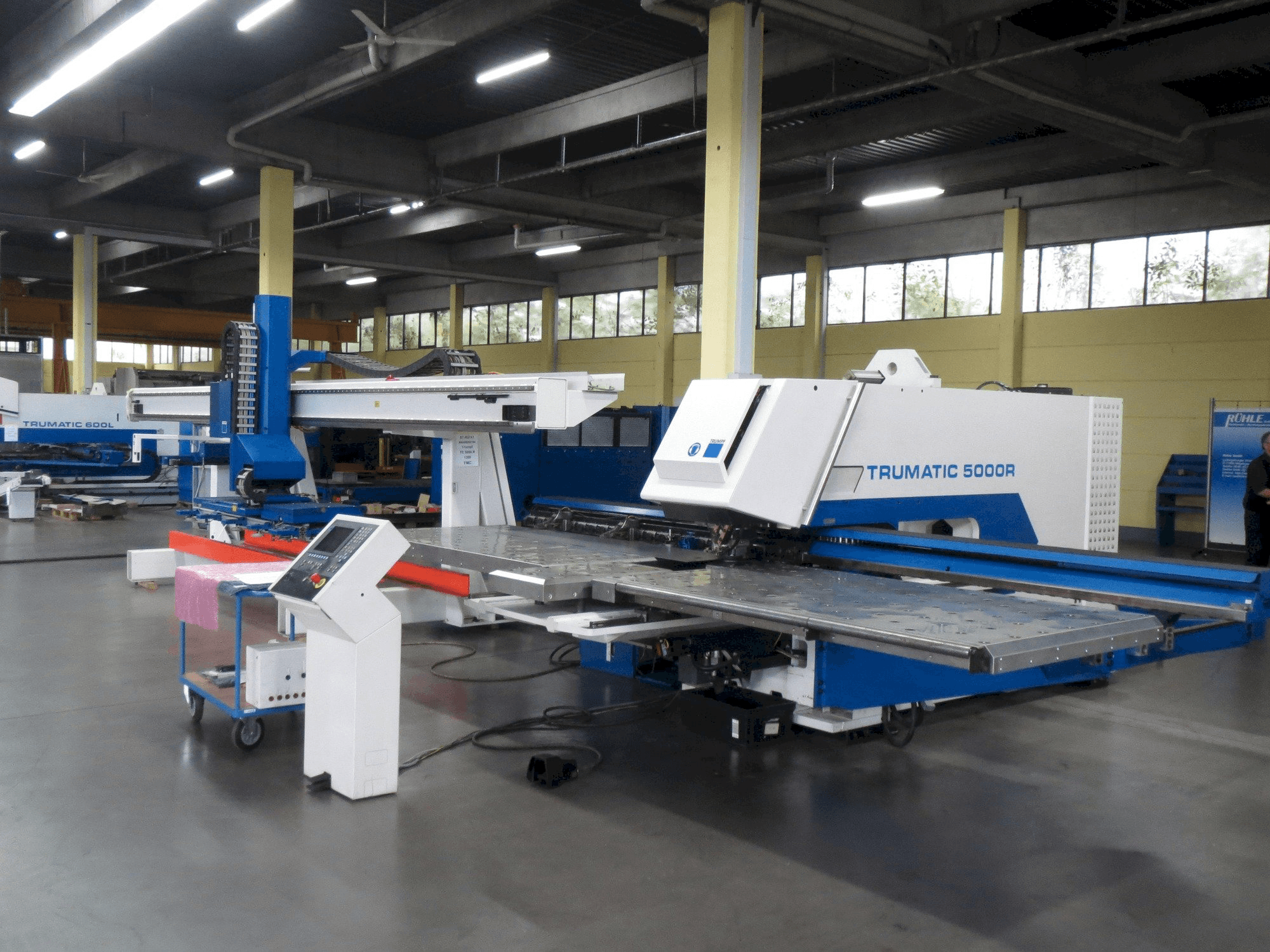

TRUMPF - Trumatic 5000 RZA-PUN-TRU-2003-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Sheet Metal Machinery

- ➤ Pre-Owned Trumpf Trumatic 5000 R Punching Machine

This Trumpf Trumatic 5000 R Punching Machine was manufactured in the year 2003 in Germany. It is operated through a Siemens Sinumerik 840 D control unit. This machine can operate with a punching force of 220 kN.

Overview

- brand: TRUMPF

- year: 2003

- MODEL: Trumatic 5000 R

- production hours: 83000

- application type: Punching

- Location: South Africa

- machine type: CNC Punch Press

- control unit brand: SIEMENS

Technical Information - TRUMPF Trumatic 5000 R

Control Unit

- Control Brand: SIEMENS

- Control Model: Sinumerik 840 D

Dimensions

- Machine Depth: 6100 mm

- Machine Height: 2500 mm

- Machine Weight: 13700 kg

Movement

- X-axis Travel: 2535 mm

Technical Specification

- Max. Sheet Thickness: 8 mm

- Punching Force: 220 Kn

Additional Information

Additional equipment

- Working Range 2500 x 1250 mm

- Stable C-frame for easy access

- Coordinate guide for high precision machining

- Linear magazine with 18 tool stations and 3 clamps

- Drives with maintenance-free 3-phase servo motors

- Repositioning unit with programmable stripper

- Ball-fitted tables

- Parts chute 500 x 500 mm

- Good parts container

- Chip container

Machine Benefits

Qualitative Machine Benefits

- Programmable presser foot

- Tool length compensation

- Spray lubrication for punches

- Vacuum slug removal

- Forming control

- Controller based on sinumerik 840d

- Control panel with tft screen 12"

- Nc program management

- Integrated technology data

- Teleservice via internet

Technical Machine Benefits

- Working area x x y: 2535 x 1280 mm

- Max. Tool diameter: 76,2 mm

- Movement speed x/y: 100/60 m/min

- Number of tool station: 18

- Automatic shut down mechanism

- First oil fillings

- Transport and assembly device punching head

- Hydraulic punching head

- Rotatable single tool adapter

- Manual adjustable presser foot force

Extra Information

- Integrated e-Shop - Production plan - Slug remove conveyer chute Safety - CE-marking - Two-beam light barriers - Rapid hydraulic shutdown - Sheet collision detection Extended equipment Punching Options - Function MultiTool - Function MultiShear - Function MultiBend - Function deburring and roll technology - StripLine - Active die Machine Options - Repositioning cylinders - Sensor for part chute Programming - Work Shop Programming based in TruTops Punch Basic Data transmission - USB interface and network connection

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing