CMS - ARES-3618-TR-PX5-Z1200US-MIL-CMS-2022-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used CMS ARES-3618-TR-PX5-Z1200 | Gantry Mill For Sale

This 5-axis CMS ARES-3618-TR-PX5-Z1200 was manufactured in 2022. It features a movable bridge design, fixed table, and all axes interpolated. The machine offers a rapid traverse of 80 m/min (X, Y) and 70 m/min (Z), with a spindle speed up to 24,000 rpm. Dual-table NC-controlled platform enhances versatility. If you are looking to get high quality milling capabilities consider the CMS ARES-3618-TR-PX5-Z1200 machine we have for sale. Contact us for more information.

Overview

- brand: CMS

- year: 2022

- MODEL: ARES-3618-TR-PX5-Z1200

- application type: Milling

- Location: United States

- machine type: Gantry Milling Machine

Technical Information - CMS ARES-3618-TR-PX5-Z1200

Movement

- X-AXIS Movement: 3600 MM

- Y-AXIS Movement: 1800 MM

- Z-AXIS Movement: 1200 MM

- B-AXIS Movement: ±120°

- C-AXIS Movement: ±270°

Additional Information

Addtional information

Axes: 5

Type: 5-Axis High-Speed Gantry Machining Center

Structure: Movable bridge design; fixed table; all 5 axes interpolated

Controller: FANUC 31i-B5

Features: Dual Check Safety, High-Speed Smooth TCP, 3D cutter compensation, helical interpolation, tilted working plane, scaling, etc.

PC: HP industrial PC, Windows 7 (32-bit), 2 GB RAM, 250 GB HDD

Spindle power: 15 kW (S1) / 19 kW (S6-40%)

Max speed: 24000 rpm

Torque: 12.1 Nm (S1) / 15.4 Nm (S6)

Cooling: Liquid (closed circuit)

Tool interface: HSK 63F

Bearings: Ceramic (front and rear)

Rapid traverse: 80 m/min (X, Y) / 70 m/min (Z)

Acceleration: 3 m/s²

Accuracy (VDI-DGQ 3441):

X: ±0.055 mm | Repeatability ±0.027 mm

Y: ±0.040 mm | Repeatability ±0.020 mm

Z: ±0.080 mm | Repeatability ±0.040 mm

Tool Magazine:

Type: 8-station automatic tool changer

Tool weight: 3 kg (max 20 kg total)

Max tool diameter: 200 mm

Max tool length: 265 mm (rear) / 165 mm (front)

Rotary table: Dual-table NC-controlled platform (rotation time ~7 s)

Table size: 2 × (2400 × 1115 mm)

Vacuum tables: 2 × (1900 × 1100 mm), aluminum, 28 mm thick

Vacuum system: 2 × dry rotary pumps, 100 m³/h each, 3 kW per pump, 10 connections per manifold, 2 manifolds total

Minimum lubrication unit: Oil mist with 3 L tank

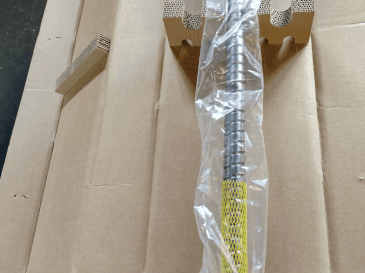

Alignment system: RENISHAW TS27R + calibrated bar

De-ionized air blower for static removal

Bellows protection: X/Y bellows + Z double scrapers

Electrical cabinet: IP54, air-conditioned

Compressed air system: 6 bar (90 PSI)

Machine colors: RAL 7035 (light grey) & RAL 7037 (dust grey)

Power Requirements:

Voltage: 480 V ±5%, 3 phases, 60 Hz (UL transformer included)

Installed power: approx. 50 kW

Included Accessories:

8 × HSK 63F toolholders

8 × ETS 32/40 collets

Tool presetting device

Standard spanners and keys

CD manuals (machine and control)

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing

Products related to CMS ARES-3618-TR-PX5-Z1200

VMX 60

Hurco - Vertical Machining Centre

CMX 70U

DMG MORI - Universal Machining Centre

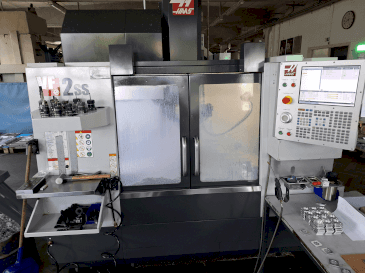

VF 2 SS

HAAS - Vertical Machining Centre

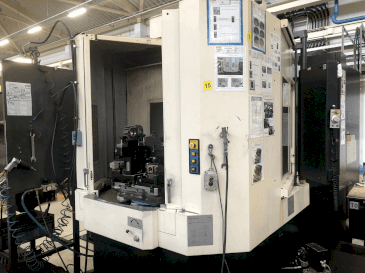

EC-400

HAAS - Horizontal Machining Centre

HM 6300

DOOSAN - Horizontal Machining Centre

A61-5XR

Makino - Horizontal Machining Centre

ACE HP 4000

DAEWOO - Vertical Machining Centre

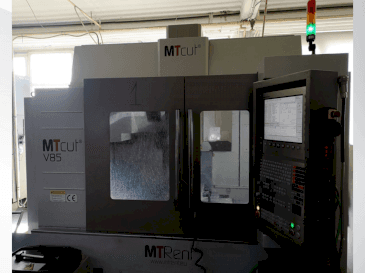

V85

MTcut - Vertical Machining Centre

MCPH150 UNIPRO 90

HELLER - Horizontal Machining Centre

DMC-63V

DECKEL - Vertical Machining Centre

VTC-300C

Mazak - Vertical Machining Centre

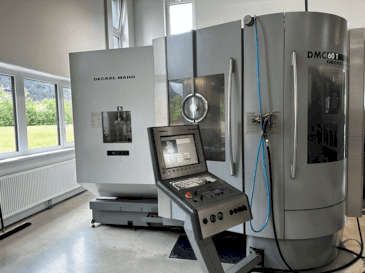

DMC 60T

DMG DECKEL MAHO - Universal Machining Centre