MVD - A-100-2600HU-BEN-MVD-2022-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Sheet Metal Machinery

- ➤ Used MVD A-100-2600 - Press For Sale | gindumac.com

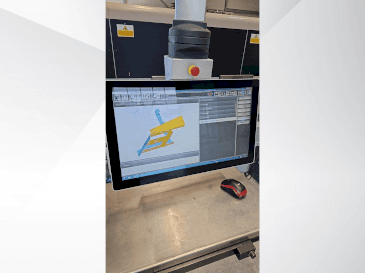

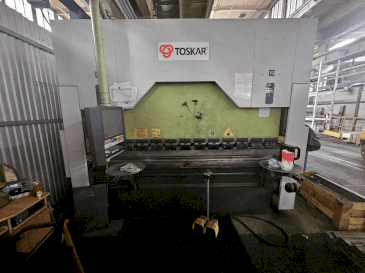

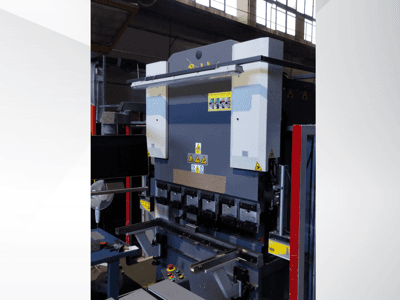

This 3-axis MVD A-100-2600 hydraulic press was manufactured in 2022. It features a robust steel frame, CNC control, and synchronized hydraulic cylinders for high bending accuracy. Equipped with German hydraulic blocks and high-quality linear encoders, it offers automatic bending adjustments and programmable working speeds. Ideal for precise, heavy-duty bending tasks. Consider the opportunity to buy this MVD A-100-2600 hydraulic press. Contact us for more information about this machine.

Overview

- brand: MVD

- year: 2022

- MODEL: A-100-2600

- application type: Bending

- Location: Hungary

- machine type: Hydraulic Press

- Available from: 28/11/2025

Technical Information - MVD A-100-2600

Additional Information

Maximum hydraulic pressure protected by safety valves

Hoerbiger or Rexroth hydraulic system in compliance with CE standards

Electrical equipment designed for 400V AC, 3-phase, 50Hz power supply

Axes: 3 (Y1, Y2, X), can work with 4 axes (Y1, Y2, X, R)

Bending force: 100 tons

Bending length: 2600 mm

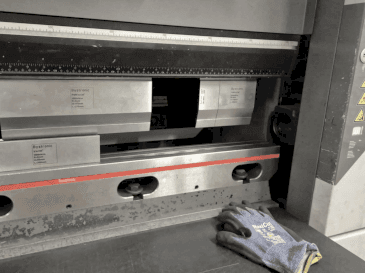

Distance between columns: 2150 mm

Stroke: 210 mm

Opening: 415 mm

Throat depth: 410 mm

C-type linear scales for precise frame deflection compensation

Multi-functional control panel and foot pedal in compliance with CE standards

User-friendly, ergonomically movable control panel

Schneider-Telemecanique electronic components placed in a sealed electrical cabinet

Maximum performance and high bending accuracy ensured by synchronized hydraulic CNC-controlled cylinders

Programmable working speed

Manual, semi-automatic, and automatic working modes

Air bending capability

Automatic pressure adjustment according to material and tooling

Automatic stroke adjustment

Automatic and programmable bending instructions according to sheet thickness, material, and tooling

Rigid, high-performance CNC-controlled rear stopper

Movable front support arms

±0.03 mm precise motorized rear stopper system

Manual fine adjustment of rear stopper fingers

European-type upper tool clamping system

Ground, hardened, upper and lower tools

Narrow table and large open height for versatile tooling

Rear light curtain (standard)

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing

Products related to MVD A-100-2600

Xpert 400/4100

Bystronic - Press Brake

MASTERFAB-2600-80

Other - Press Brake

HFE 80-25 L

AMADA - Press Brake

Xpert 40/1030

Bystronic - Press Brake

APHS 41600

Baykal - Press Brake

TrumaBend V130

TRUMPF - Press Brake

APHS 31120

Baykal - Press Brake

APHS 31440

Baykal - Press Brake

E-Brake B 50-2050

SAFAN - Press Brake

APHS 125040

Baykal - Press Brake

TrumaBend V85

TRUMPF - Press Brake

PPEB 170/40

LVD - Press Brake